Buick Encore: Vehicle access - Diagnostic information and procedures

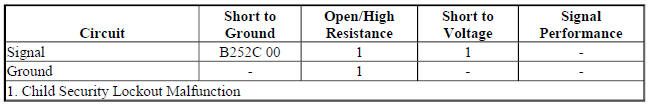

DTC B252C: Child security lock switch circuit

DIAGNOSTIC CODE INDEX

.jpg)

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptor

DTC B252C 00

Child Security Lock Switch Circuit

Diagnostic Fault Information

Circuit/System Description

The Body Control Module monitors the voltage level in the child security door lockout switch signal circuit, when the switch is in the open position the voltage in the signal circuit will be equal to the B+ voltage level.

When the child security door lockout switch is pressed, voltage within the signal circuit drops and the Body Control Module will detect the voltage drop and will energize the Door Lock relay to disable the interior rear door handles.

Conditions for Running the DTC

The system voltage is 9-16 V.

Conditions for Setting the DTC

The Body Control Module has detected a short to ground on the child security lockout switch signal circuit for greater than 60 seconds.

Action Taken When the DTC Sets

- The interior rear door handles will always be disabled or will not lockout depending upon the latch states when the fault occurred

- The Body Control Module will ignore the input from the lockout switch.

Conditions for Clearing the DTC

- The DTC will be current for as long as the fault is present.

- When the fault is no longer present, the DTC will be a history DTC.

- A history DTC will clear after 50 ignition cycles.

Reference Information

Schematic Reference

Door Lock/Indicator Schematics (Encore), Door Lock/Indicator Schematics (Encore)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Description and Operation

Power Door Locks Description and Operation

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Verification

- Ignition ON.

- Verify the scan tool Left Rear Child Security Lock Switch and Right Rear Child Security Lock Switch parameters change between Inactive and Active when pressing and depressing the child security lockout switch.

- If the parameters do not change

Refer to Circuit/System Testing.

- If the parameters change

- All OK.

Circuit/System Testing

- Ignition OFF and all vehicle systems OFF, disconnect the harness connector at the S48E Multifunction Switch-Center Console. It may take up to 2 minutes for all vehicle systems to power down.

- Test for less than 10 ohms between the ground circuit terminal 9 and ground.

- If 10 ohms or greater

- Ignition OFF.

- Test for less than 2 ohms in the ground circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, repair the open/high resistance in the ground connection.

- If less than 10 ohms

- Ignition ON.

- Test for greater than 10 V between the signal circuit terminal 3 and ground.

- If 10 V or less

- Ignition OFF, disconnect the harness connector at the K9 Body Control Module.

- Test for infinite resistance between the signal circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit

- Test for less than 2 ohms in the signal circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K9 Body Control Module.

- If greater than 10 V

- Test or replace the S48E Multifunction Switch-Center Console.

Component Testing

- Ignition OFF, disconnect the harness connector at the S48E Multifunction Switch-Center Console.

- Test for infinite resistance between the signal terminal 3 and the ground terminal 9 with the switch in the open position.

- If less than infinite resistance

Replace the S48E Multifunction Switch-Center Console.

- If infinite resistance

- Test for less than 3 ohms between the signal terminal 3 and the ground terminal 9 with the switch in the closed position.

- If 3 ohms or greater

Replace the S48E Multifunction Switch-Center Console.

- If less than 3 ohms

- All OK

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Instrument Panel Multifunction Switch Replacement (Encore)

- Control Module References for the Body Control Module replacement, programming and setup

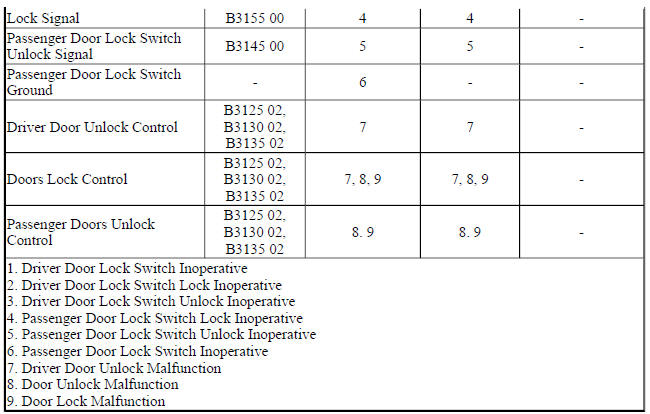

DTC B3125, B3130, OR B3135: Driver door only unlock/all doors lock/unlock

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptors

DTC B3125

Driver Door Only Unlock Circuit

DTC B3130

All Doors Unlock Circuit

DTC B3135

All Doors Lock Circuit

For symptom byte information refer to: Symptom Byte List

Diagnostic Fault Information

.jpg)

.jpg)

Circuit/System Description

The body control module (BCM) controls the driver and passenger door latches. When the BCM receives a driver door unlock, passenger door unlock or all door lock command, it will provide voltage to the appropriate door lock circuits and ground to the opposite door lock circuits causing the actuator to perform the lock or unlock function.

Conditions for Running the DTC

When the output is actively being requested by the BCM.

Conditions for Setting the DTC

B3125 02, B3130 02 and B3135 02

- A short to ground or an open/high resistance in the BCM B+ circuit.

- The BCM detects a short to ground on a door latch control circuit.

Action Taken When the DTC Sets

The power door locks will be inoperative

Conditions for Clearing the DTC

- The DTC will be current for as long as the fault is present.

- When the fault is no longer present, the DTC will be a history DTC.

- A history DTC will clear after 50 ignition cycles.

Reference Information

Schematic Reference

- Door Lock/Indicator Schematics (Encore), Door Lock/Indicator Schematics (Encore)

- Body Control System Schematics (Encore) , Body Control System Schematics (Encore)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Description and Operation

Power Door Locks Description and Operation

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Verification

- Ignition ON.

- Verify all vehicle doors LOCK and UNLOCK when commanding the All Doors Lock/Unlock with a scan tool.

- If only the driver door LOCK or UNLOCK functions do not work

Refer to Power Door Locks Malfunction.

- If one or more, but not all, passenger door LOCK or UNLOCK functions do not work Refer to Power Door Locks Malfunction.

- If all door LOCK and UNLOCK functions do not work

Refer to Circuit/System Testing

- If the LOCK and UNLOCK function for all doors works

- All OK.

Circuit/System Testing

- Ignition OFF, disconnect the X2 harness connector at the K9 Body Control Module, ignition ON.

- Verify a test lamp illuminates between the B+ circuit terminal 4 and ground.

If the test lamp does not illuminate and the circuit fuse is good

- Ignition OFF.

- Test for less than 2 ohms in the B+ circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, verify the fuse is not open and there is voltage at the fuse.

- If the test lamp does not illuminate and the circuit fuse is open

- Ignition OFF.

- Test for infinite resistance between the B+ circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance

- Disconnect the harness connector at each of the A23 Door Latch Assemblies.

- Test for infinite resistance between each control circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance, replace the appropriate A23 Door Latch Assembly.

- If the test lamp illuminates

- Ignition OFF, connect the X2 harness connector at the K9 Body Control Module. Disconnect the harness connector at the A23D Door Latch Assembly-Driver, ignition ON.

NOTE:

Leaving the DMM connected between a control circuit and ground for greater than 20 seconds will cause the K9 Body Control Module to interpret the test as a system fault and will cause the voltage on the control circuit to drop to 0 V. If the voltage drops to 0 V, operate the door locks using the door lock switch to restore the voltage for testing.

- Test for greater than 5 V between the control circuit terminal 2 and ground.

- If 5 V or less

- Ignition OFF, disconnect the X6 harness connector at the K9 Body Control Module.

- Test for infinite resistance between the control circuit terminal listed below and ground:

- Control circuit terminal 1 X6

- Control circuit terminal 2 X6

- Control circuit terminal 4 X6

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance, replace the K9 Body Control Module.

- If greater than 5 V

- Verify that a test lamp does not illuminate between the control circuit terminal 2 and ground

- If the test lamp illuminates

- Ignition OFF, disconnect the X6 harness connector at the K9 Body Control Module

- Test for less than 1 V between the control circuit terminal listed below and ground:

- Control circuit terminal 1 X6

- Control circuit terminal 2 X6

- Control circuit terminal 4 X6

- If greater than 1 V, repair the short to voltage on the circuit.

- If less than 1 V, replace the K9 Body Control Module.

- If the test lamp does not illuminate

- Replace the K9 Body Control Module.

Component Testing

- Ignition OFF, disconnect the harness connector at the appropriate A23 Door Latch Assembly.

- Install a 25 A fused jumper wire between one of the control terminals and 12 V. Momentarily install a jumper wire between the other control terminal and ground. Reverse the jumper wires at least two times, the A23 Door Latch Assembly should perform the LOCK and UNLOCK function.

- If the actuator does not perform the LOCK and UNLOCK function

Replace the A23 Door Latch Assembly.

- If the actuator performs the LOCK and UNLOCK function

- All OK

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Front Side Door Latch Replacement

- Rear Side Door Latch Replacement

- Control Module References for BCM replacement, programming and setup

DTC B3140, B3145, B3150, OR B3155: Door lock/unlock switch

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category

DTC Descriptors

DTC B3140 00

Driver Door Unlock Switch Circuit

DTC B3145 00

Passenger Door Unlock Switch Circuit

DTC B3150 00

Driver Front Door Lock Switch Circuit

DTC B3155 00

Passenger Front Door Lock Switch Circuit

Diagnostic Fault Information

.jpg)

.jpg)

Circuit/System Description

The body control module (BCM) supplies a 12 V signal to each of the door lock and door unlock signal circuits.

When the door lock switches are in the open position, the voltage level in the signal circuit will be near 12 V.

When any door lock switch is pressed to the lock or unlock position, the voltage level in the appropriate signal circuit will drop to 0 V and the BCM will detect the voltage drop and command the door latches to perform the requested lock or unlock command.

Conditions for Running the DTC

The system voltage is 9-16 V.

Conditions for Setting the DTC

B3140 00

The BCM detects short to ground in the driver unlock signal circuit for greater than 30 seconds.

B3145 00

The BCM detects short to ground in the passenger unlock signal circuit for greater than 30 seconds.

B3150 00

The BCM detects a short to ground in the driver lock signal circuit for greater than 30 seconds.

B3155 00

The BCM detects a short to ground in the passenger lock signal circuit for greater than 30 seconds.

Action Taken When the DTC Sets

B3140 00

The BCM will ignore the unlock signal and the doors will not unlock when using the driver door unlock switch.

B3145 00

The BCM will ignore the unlock signal and the doors will not unlock when using the passenger door unlock switch.

B3150 00

The BCM will ignore the lock signal and the doors will not lock when using the driver door lock switch.

B3155 00

The BCM will ignore the lock signal and the doors will not lock when using the passenger door lock switch.

Conditions for Clearing the DTC

- The DTC will be current for as long as the fault is present.

- When the fault is no longer present, the DTC will be a history DTC.

- A history DTC will clear after 50 ignition cycles.

Reference Information

Schematic Reference

Door Lock/Indicator Schematics (Encore), Door Lock/Indicator Schematics (Encore)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Description and Operation

Power Door Locks Description and Operation

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Verification

- Ignition ON.

- Verify the scan tool Driver Door Lock Switch parameter changes from Inactive to Lock and Unlock when pushing the appropriate switch on the S13D Door Lock Switch - Driver.

- If the parameter does not change

Refer to Circuit/System Testing - Driver Door Lock Switch Malfunction.

- If the parameter changes

- Verify the scan tool Passenger Door Lock Switch parameter changes from Inactive to Lock and Unlock when pushing the appropriate switch on the S13P Door Lock Switch - Passenger.

- If the parameter does not change

Refer to Circuit/System Testing - Passenger Door Lock Switch Malfunction.

- If the parameter changes

- All OK.

Circuit/System Testing

Driver Door Lock Switch Malfunction

- Ignition OFF and all vehicle systems OFF, disconnect the harness connector at the S13D Door Lock Switch - Driver. It may take up to 2 minutes for all vehicle systems to power down.

- Test for less than 10 ohms between the ground circuit terminal 3 and ground.

- If 10 ohms or greater

- Ignition OFF.

- Test for less than 2 ohms in the ground circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, repair the open/high resistance in the ground connection.

- If less than 10 ohms

- Ignition ON.

- Verify the scan tool Driver Door Lock Switch parameter is Inactive.

If not Inactive

- Ignition OFF, disconnect the harness connector at the K9 Body Control Module.

- Test for infinite resistance between the signal circuit terminal 4 and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- Test for infinite resistance between the signal circuit terminal 2 and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance, replace the K9 Body Control Module.

- If Inactive

- Install a 3 A fused jumper wire between the signal circuit terminal 4 and the ground circuit terminal 3.

- Verify the scan tool Driver Door Lock Switch parameter is Lock.

- If not Lock

- Ignition OFF, remove the 3 A fused jumper wire, disconnect the harness connector at the K9 Body Control Module, ignition ON.

- Test for less than 1 V between the signal circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V

- Test for less than 2 ohms in the signal circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K9 Body Control Module.

- If Lock

- Install a 3 A fused jumper wire between the signal circuit terminal 2 and the ground circuit terminal 3.

- Verify the scan tool Driver Door Lock Switch parameter is Unlock.

- If not Unlock

- Ignition OFF, 3 A fused jumper wire, disconnect the harness connector at the K9 Body Control Module, ignition ON.

- Test for less than 1 V between the signal circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V

- Test for less than 2 ohms in the signal circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K9 Body Control Module.

- If Unlock

- Test or replace the S13D Door Lock Switch - Driver.

Passenger Door Lock Switch Malfunction

- Ignition OFF and all vehicle systems OFF, disconnect the harness connector at the S13P Door Lock Switch - Passenger. It may take up to 2 minutes for all vehicle systems to power down.

- Test for less than 10 ohms between the ground circuit terminal 3 and ground.

If 10 ohms or greater

- Ignition OFF.

- Test for less than 2 ohms in the ground circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, repair the open/high resistance in the ground connection.

- If less than 10 ohms

- Ignition ON.

- Verify the scan tool Passenger Door Lock Switch parameter is Inactive.

- If not Inactive

- Ignition OFF, disconnect the harness connector at the K9 Body Control Module.

- Test for infinite resistance between the signal circuit terminal 4 and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- Test for infinite resistance between the signal circuit terminal 2 and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance, replace the K9 Body Control Module.

- If Inactive

- Install a 3 A fused jumper wire between the signal circuit terminal 4 and the ground circuit terminal 3.

- Verify the scan tool Passenger Door Lock Switch parameter is Lock.

- If not Lock

- Ignition OFF, 3 A fused jumper wire, disconnect the harness connector at the K9 Body Control Module, ignition ON.

- Test for less than 1 V between the signal circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V

- Test for less than 2 ohms in the signal circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K9 Body Control Module.

- If Lock

- Install a 3 A fused jumper wire between the signal circuit terminal 2 and the ground circuit terminal 3.

- Verify the scan tool Passenger Door Lock Switch parameter is Unlock.

If not Unlock

- Ignition OFF, 3 A fused jumper wire, disconnect the harness connector at the K9 Body Control Module, ignition ON.

- Test for less than 1 V between the signal circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V

- Test for less than 2 ohms in the signal circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K9 Body Control Module.

- If Unlock

- Test or replace the S13P Door Lock Switch - Passenger.

Component Testing

Driver Door Lock Switch

- Ignition OFF, disconnect the harness connector at the S13D Door Lock Switch - Driver.

- Test for infinite resistance between the signal terminal 2 and the ground terminal 3 with the switch in the center position.

- If less than infinite resistance

Replace the S13D Door Lock Switch - Driver.

- If infinite resistance

- Test for infinite resistance between the signal terminal 4 and the ground terminal 3 with the switch in the center position.

- If less than infinite resistance

Replace the S13D Door Lock Switch - Driver

- If infinite resistance

- Test for less than 2 ohms between the signal terminal 4 and the ground terminal 3 with the switch in the Lock position

- If 2 ohms or greater

Replace the S13D Door Lock Switch - Driver.

- If less than 2 ohms

- Test for less than 2 ohms between the signal terminal 2 and the ground terminal 3 with the switch in the Unlock position.

- If 2 ohms or greater

Replace the S13D Door Lock Switch - Driver.

- If less than 2 ohms

- All OK

Passenger Door Lock Switch

- Ignition OFF, disconnect the harness connector at the S13P Door Lock Switch - Passenger.

- Test for infinite resistance between the signal terminal 2 and the ground terminal 3 with the switch in the center position

- If less than infinite resistance

Replace the S13P Door Lock Switch - Passenger.

- If infinite resistance

- Test for infinite resistance between the signal terminal 4 and the ground terminal 3 with the switch in the center position.

- If less than infinite resistance

Replace the S13P Door Lock Switch - Passenger

- If infinite resistance

- Test for less than 2 ohms between the signal terminal 4 and the ground terminal 3 with the switch in the Lock position.

- If 2 ohms or greater

Replace the S13P Door Lock Switch - Passenger.

- If less than 2 ohms

- Test for less than 2 ohms between the signal terminal 2 and the ground terminal 3 with the switch in the Unlock position.

- If 2 ohms or greater

Replace the S13P Door Lock Switch - Passenger.

- If less than 2 ohms

- All OK

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Door Lock Switch Replacement - Driver Side (Encore), Door Lock Switch Replacement - Driver Side (Encore)

- Door Lock Switch Replacement - Passenger Front (Encore), Door Lock Switch Replacement - Passenger Front (Encore)

- Control Module References for BCM replacement, programming and setup

DTC B3245: Rear cargo door lock actuator circuit

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptors

DTC B3245

Rear Cargo Door Lock Actuator Circuit

For symptom byte information refer to: Symptom Byte List

Diagnostic Fault Information

.jpg)

Circuit/System Description

When the body control module (BCM) receives a liftgate release command, it will provide voltage to one side of the relay and ground to the other side of the relay. This will energize the relay causing the switch side of the relay to close and will then provide B+ voltage to the liftgate latch.

Conditions for Running the DTC

- The system voltage is 9-16 V.

- When the relay is actively commanded by the BCM.

Conditions for Setting the DTC

B3245 01

The BCM detects a short to voltage in the liftgate unlatch relay control circuit.

B3245 02

The BCM detects a short to ground in the liftgate unlatch relay control circuit.

Action Taken When the DTC Sets

The liftgate latch will be inoperative.

Conditions for Clearing the DTC

- The DTC will be current for as long as the fault is present.

- When the fault is no longer present, the DTC will be a history DTC.

- A history DTC will clear after 50 ignition cycles.

Reference Information

Schematic Reference

Release Systems Schematics (Encore), Release Systems Schematics (Encore)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Description and Operation

Rear Hatch/Gate Description and Operation

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Verification

- Ignition ON.

- Verify the M30 Liftgate Latch functions when commanding the Liftgate Unlatch with a scan tool.

- If the M30 Liftgate Latch does not function

Refer to Circuit/System Testing.

- If the M30 Liftgate Latch does function

- All OK

Circuit/System Testing

- Ignition OFF, disconnect the KR95A Liftgate Unlatch Relay. Ignition ON.

- Connect a test lamp between the control circuit terminal 2 and ground.

- Verify the test lamp turns ON and OFF when commanding the Liftgate Unlatch with a scan tool.

- If the test lamp is always OFF

- Ignition OFF, remove the test lamp, disconnect the harness connector at the K9 Body Control Module.

- Test for infinite resistance between the control circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance

- Test for less than 2 ohms in the control circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K9 Body Control Module.

- If the test lamp is always ON

- Ignition OFF, remove the test lamp, disconnect the harness connector at the K9 Body Control Module, ignition ON.

- Test for less than 1 V between the control circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit

- If less than 1 V, replace the K9 Body Control Module

- If the test lamp turns ON and OFF

- Connect a test lamp between the control circuit terminal 1 and B+.

- Verify the test lamp turns ON and OFF when commanding the Liftgate Unlatch with a scan tool.

- If the test lamp is always OFF

- Ignition OFF, remove the test lamp, disconnect the harness connector at the K9 Body Control Module, ignition ON.

- Test for less than 1 V between the control circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V

- Ignition OFF.

- Test for less than 2 ohms in the control circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K9 Body Control Module.

- If the test lamp is always ON

- Ignition OFF, remove the test lamp, disconnect the harness connector at the K9 Body Control Module.

- Test for infinite resistance between the control circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance, replace the K9 Body Control Module.

- If the test lamp turns ON and OFF

- Test or replace the KR95A Liftgate Unlatch Relay.

Component Testing

Relay Test

- Ignition OFF, disconnect the KR95A Liftgate Unlatch Relay.

- Test for 60-200 ohms between terminals 85 and 86.

- If less than 60 or greater than 200

Replace the KR95A Liftgate Unlatch Relay.

- If between 60-200 ohms

- Test for infinite resistance between the terminals listed below:

- 30 and 86

- 30 and 87

- 30 and 85

- 85 and 87

- If less than infinite resistance

Replace the KR95A Liftgate Unlatch Relay.

- If infinite resistance

- Install a 3 A fused jumper wire between relay terminal 85 and 12 V. Install a jumper wire between relay terminal 86 and ground.

- Test for less than 2 ohms between terminals 30 and 87.

- If 2 ohms or greater

Replace the KR95A Liftgate Unlatch Relay.

- If less than 2 ohms

- All OK

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Relay Replacement (Within an Electrical Center) , Relay Replacement (Attached to Wire Harness)

- Control Module References for BCM replacement, programming and setup

DTC B3930: Child security lock motors

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category

DTC Descriptors

DTC B3930 01

Child Security Lock Motors Circuit Short to Battery

DTC B3930 02

Child Security Lock Motors Circuit Short to Ground

DTC B3930 04

Child Security Lock Motors Circuit Open

Diagnostic Fault Information

.jpg)

.jpg)

Circuit/System Description

The body control module controls the child security lock relay when it receives a command to lockout the rear doors. The relay will apply voltage to both child security circuits at the rear door latches to disable the interior rear door handles.

Conditions for Running the DTC

When the Door Lock relay is being actively commanded by the body control module.

Conditions for Setting the DTC

B3930 01

The body control module detects a short to voltage or an open/high resistance in the door lock security relay control circuit.

The body control module detects a an open/high resistance in the underhood fuse block ground circuit.

The body control module detects a short to ground or an open/high resistance in the body control module B+ circuit.

B3930 02

The BCM detects a short to ground in the door lock security relay control circuit.

B3930 04

The body control module detects a short to voltage or an open/high resistance in the door lock security relay control circuit.

The body control module detects a an open/high resistance in the underhood fuse block ground circuit.

The body control module detects a short to ground or an open/high resistance in the body control module B+ circuit.

Action Taken When the DTC Sets

- The interior rear door handles will always be disabled or will not lockout depending upon the latch states when the fault occurred

- The body control module will command the lockout indicator to flash ON and OFF for 30 seconds when the lockout switch is pressed to indicate a fault in the system.

Conditions for Clearing the DTC

- The DTC will be current for as long as the fault is present.

- When the fault is no longer present, the DTC will be a history DTC.

- A history DTC will clear after 50 ignition cycles

Reference Information

Schematic Reference

Door Lock/Indicator Schematics (Encore), Door Lock/Indicator Schematics (Encore)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Description and Operation

Power Door Locks Description and Operation

Electrical Information Reference

- Testing for Intermittent Conditions and Poor Connections

- Circuit Testing

- Wiring Repairs

- Connector Repairs

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Verification

- Ignition ON.

- Verify both interior rear door handles do not open the rear doors when commanding the Child Security Lock Motors ON with a scan tool.

- If both interior door handles open the rear doors

Refer to Circuit/System Testing.

- If both interior door handles do not open the rear doors

- Verify both interior rear door handles will open the rear doors when commanding the Child Security Lock Motors OFF with a scan tool.

- If both interior door handles do not open the rear doors

Refer to Circuit/System Testing

- If both interior door handles open the rear doors

- All OK

Circuit/System Testing

- Ignition OFF and all vehicle systems OFF, disconnect the X2 harness connector at the X50A Fuse Block- Underhood. It may take up to 2 minutes for all vehicle systems to power down.

- Test for less than 10 ohms between the ground circuit terminal C5 and ground.

- If 10 ohms or greater

- Ignition OFF.

- Test for less than 2 ohms in the ground circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, repair the open/high resistance in the ground connection.

- If less than 10 ohms

- Ignition OFF, connect the X2 harness connector at the X50A Fuse Block-Underhood. Disconnect the X4 harness connector at the K9 Body Control Module, ignition ON.

- Verify that a test lamp does not illuminate between the control circuit terminal 8 and ground.

- If the test lamp illuminates

- Ignition OFF, remove the test lamp, disconnect the X2 harness connector at the X50A Fuse Block- Underhood.

- Test for less than 1 V between the K9 Body Control Module control circuit terminal 8 X4 and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V, replace the X50A Fuse Block-Underhood.

- If the test lamp is not illuminated

- Connect a 3A fused jumper wire between the control circuit terminal 8 and B+.

- Listen for an audible click from the X50A Fuse Block-Underhood as the KR113 Child Security Lock Disable Relay activates.

- If the KR113 Child Security Lock Disable Relay does not activate

- Ignition OFF, remove the jumper wire, disconnect the X2 harness connector at the X50A Fuse Block-Underhood.

- Test for infinite resistance between the K9 Body Control Module control circuit terminal 8 X4 and ground.

- If less than Infinite resistance, repair the short to ground on the circuit.

- If infinite resistance

- Test for less than 2 ohms in the control circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the X50A Fuse Block-Underhood.

- If the KR113 Child Security Lock Disable Relay activates

- Replace the K9 Body Control Module.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Front Compartment Fuse Block Replacement

- Control Module References body control module replacement, programming and setup

SYMPTOMS - VEHICLE ACCESS

NOTE: The following steps must be completed before using the symptom tables.

- Perform the Diagnostic System Check - Vehicle , before using the Symptom Tables in order to verify that all of the following are true:

- There are no DTCs set

- The control modules can communicate via the serial data link

- Review the system operation in order to familiarize yourself with the system functions. Refer to the following systems description:

- Door Ajar Indicator Description and Operation

- Rear Hatch/Gate Description and Operation

- Power Door Locks Description and Operation

Visual/Physical Inspection

- Inspect for aftermarket devices which may affect the operation of the system. Refer to Checking Aftermarket Accessories .

- Inspect the easily accessible or visible system components for obvious damage or conditions which may cause the symptom.

Intermittent

Faulty electrical connections or wiring may be the cause of intermittent conditions. Refer to Testing for Intermittent Conditions and Poor Connections .

Symptom List

Refer to a symptom diagnostic procedure from the following list in order to diagnose the symptom:

- Power Door Child Lock Malfunction

- Door Ajar Indicator Malfunction

- Power Door Locks Malfunction

- Liftgate Release Malfunction

Fuel filler door release malfunction (NO8)

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

Diagnostic Fault Information

.jpg)

Circuit/System Description

The locking and unlocking of the fuel door is a function of the power door lock system. The fuel door lock actuator shares the circuit with the door latch unlock control circuit. The body control module (BCM), upon receipt of a lock switch lock or unlock signal, will switch the appropriate door latch, as well as a fuel door lock actuator control circuits to B+ voltage. The opposing side of the door latch and fuel door lock actuator control circuit is pulled to ground by the BCM through the other the door latch control circuits, along with the fuel door lock actuator, will lock or unlock as commanded.

Reference Information

Schematic Reference

Door Lock/Indicator Schematics (Encore), Door Lock/Indicator Schematics (Encore)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Description and Operation

Fuel Fill Door Description and Operation (NO8 Only)

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

Scan Tool Reference

- Control Module References for scan tool information

- Circuit/System Verification

- Ignition ON.

- Verify the M97 Fuel Door Lock Actuator does not release the fuel filler door when commanding the All Doors Lock/Unlock to Lock with a scan tool.

- If the M97 Fuel Door Lock Actuator releases the fuel filler door

Refer to Circuit/System Testing.

- If the M97 Fuel Door Lock Actuator does not release the fuel filler door

- Verify the M97 Fuel Door Lock Actuator releases the fuel filler door when commanding the All Doors Lock/Unlock to Unlock with a scan tool.

- If the M97 Fuel Door Lock Actuator does not release the fuel filler door

Refer to Circuit/System Testing.

- If the M97 Fuel Door Lock Actuator releases the fuel filler door

- All OK.

Circuit/System Testing

- Ignition OFF, disconnect the harness connector at the M97 Fuel Door Lock Actuator.

- Connect a test lamp between control circuit terminal 1 and control circuit terminal 2, ignition ON.

- Verify the test lamp turns ON when commanding the All Doors Lock/Unlock with a scan tool.

If the test lamp remains OFF during either of the commands

- Ignition OFF, remove the test lamp, disconnect the harness connector at the K9 Body Control Module.

- Test for infinite resistance between each control circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance, replace the K9 Body Control Module.

- Test for less than 2 ohms in each control circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K9 Body Control Module.

- If the test lamp turns ON during each of the commands

- Test or replace the M97 Fuel Door Lock Actuator.

Component Testing

Fuel Door Latch

- Ignition OFF, disconnect the harness connector at the M97 Fuel Door Lock Actuator.

- Install a 25 A fused jumper wire between one of the control terminals and 12 V. Momentarily install a jumper wire between the other control terminal and ground. Reverse the jumper wires at least two times, the M97 Fuel Door Lock Actuator should perform the LOCK and UNLOCK function.

- If the actuator does not perform the LOCK and UNLOCK function

Replace the M97 Fuel Door Lock Actuator.

- If the actuator performs the LOCK and UNLOCK function

- All OK

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Fuel Tank Filler Door Latch Housing Replacement (Encore) , Fuel Tank Filler Door Latch Housing Replacement (Encore)

- Control Module References for BCM replacement, programming and setup

Liftgate release malfunction

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

Diagnostic Fault Information

.jpg)

.jpg)

Circuit/System Description

The liftgate unlatch switch is an input to the body control module (BCM). The BCM supplies a 12 V signal to the liftgate unlatch switch and when the switch is pressed, signal circuit voltage goes low. When the BCM receives a liftgate release signal it will monitor the status to the door latches. If the vehicle doors are locked, the BCM will ignore the request, if the doors are unlocked, the BCM will supply voltage and ground to the liftgate release relay coil, energizing the relay. When the relay is energized, battery voltage flows through the closed contacts of the relay to the liftgate latch assembly which activates allowing for the liftgate to be raised to the open position.

Diagnostic Aids

An intermittent short to ground in the liftgate unlatch switch signal circuit may cause the BCM to command the liftgate to open if the vehicle is in park and the doors are unlocked. If the vehicle has a history of the liftgate opening unexpectedly, inspect the point where the wires enter the liftgate unlatch switch for corrosion or evidence of water intrusion.

Reference Information

Schematic Reference

Release Systems Schematics (Encore), Release Systems Schematics (Encore)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Description and Operation

Rear Hatch/Gate Description and Operation

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Verification

- Ignition ON.

- Verify the scan tool Trunk Lid/Liftgate Window Exterior Unlatch Switch parameter changes between Inactive and Active when pressing the S46B Liftgate Unlatch Switch.

- If the parameter does not change

Refer to Circuit/System Testing - Liftgate Release Switch Inoperative.

- If the parameter changes

NOTE:

Verify all doors have been commanded UNLOCK with a scan tool prior to commanding the liftgate to unlatch

- Verify the M30 Liftgate Latch functions when commanding the Liftgate Unlatch with a scan tool.

- If the M30 Liftgate Latch does not UNLATCH

Refer to Circuit/System Testing - Liftgate Latch Inoperative

- If the M30 Liftgate Latch does UNLATCH

- All OK.

Circuit/System Testing

Liftgate Release Switch Inoperative

- Ignition OFF and all vehicle systems OFF, disconnect the harness connector at the S46B Liftgate Unlatch Switch. It may take up to 2 minutes for all vehicle systems to power down.

- Test for less than 10 ohms between the ground circuit terminal 2 and ground.

- If 10 ohms or greater

- Ignition OFF.

- Test for less than 2 ohms in the ground circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, repair the open/high resistance in the ground connection.

- If less than 10 ohms

- Ignition ON.

- Verify the scan tool Trunk Lid/Liftgate Window Exterior Unlatch Switch parameter is Inactive.

- If not Inactive

- Ignition OFF, disconnect the harness connector at the K9 Body Control Module.

- Test for infinite resistance between the signal circuit terminal 1 and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance, replace the K9 Body Control Module.

- If Inactive

- Install a 3 A fused jumper wire between the signal circuit terminal 1 and the ground circuit terminal 2.

- Verify the scan tool Trunk Lid/Liftgate Window Exterior Unlatch Switch parameter is Active

- If not Active

- Ignition OFF, remove the jumper wire, disconnect the harness connector at the K9 Body Control Module, ignition ON.

- Test for less than 1 V between the signal circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V

- Test for less than 2 ohms in the signal circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K9 Body Control Module.

- If Active

- Test or replace the S46B Liftgate Unlatch Switch.

Liftgate Latch Inoperative

- Ignition OFF, disconnect the KR95A Liftgate Unlatch Relay. Ignition ON.

- Verify a test lamp illuminates between the B+ circuit terminal 3 and ground.

- If the test lamp does not illuminate and the circuit fuse is good

- Ignition OFF.

- Test for less than 2 ohms in the B+ circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, verify the fuse is not open and there is voltage at the fuse.

- If the test lamp does not illuminate and the circuit fuse is open

- Ignition OFF.

- Test for infinite resistance between the B+ circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance

- Disconnect the harness connector at the M30 Liftgate Latch.

- Test for infinite resistance between the control circuit terminal 5 and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance, replace the KR95A Liftgate Unlatch Relay

- If the test lamp illuminates

- Connect a test lamp between the control circuit terminal 2 and ground.

- Ignition ON, verify the test lamp turns ON and OFF when commanding the Liftgate Unlatch with a scan tool.

- If the test lamp is always OFF

- Ignition OFF, remove the test lamp, disconnect the harness connector at the K9 Body Control Module.

- Test for infinite resistance between the control circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance

- Test for less than 2 ohms in the control circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K9 Body Control Module.

- If the test lamp is always ON

- Ignition OFF, remove the test lamp, disconnect the harness connector at the K9 Body Control Module, ignition ON.

- Test for less than 1 V between the control circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V, replace the K9 Body Control Module.

- If the test lamp turns ON and OFF

- Connect a test lamp between the control circuit terminal 1 and B+.

- Verify the test lamp turns ON and OFF when commanding the Liftgate Unlatch with a scan tool.

- If the test lamp is always OFF

- Ignition OFF, remove the test lamp, disconnect the harness connector at the K9 Body Control Module, ignition ON.

- Test for less than 1 V between the control circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V

- Ignition OFF.

- Test for less than 2 ohms in the control circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K9 Body Control Module.

- If the test lamp is always ON

- Ignition OFF, remove the test lamp, disconnect the harness connector at the K9 Body Control Module.

- Test for infinite resistance between the control circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance, replace the K9 Body Control Module.

- If the test lamp turns ON and OFF

- Verify that a test lamp does not illuminate between the control circuit terminal 5 and ground.

- If the test lamp illuminates

Repair the short to voltage on the control circuit

- If the test lamp does not illuminate

- Ignition OFF and all vehicle systems OFF, disconnect the harness connector at the M30 Liftgate Latch. It may take up to 2 minutes for all vehicle systems to power down.

- Test for less than 10 ohms between the ground circuit terminal 1 and ground.

- If 10 ohms or greater

- Ignition OFF.

- Test for less than 2 ohms in the ground circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, repair the open/high resistance in the ground connection.

- If less than 10 ohms

- Connect the harness connector at the M30 Liftgate Latch

- Ignition ON, connect a 10 A fused jumper wire between the B+ circuit terminal 3 and the control circuit terminal 5.

- Verify the M30 Liftgate Latch is activated.

- If the M30 Liftgate Latch does not activate

- Ignition OFF, disconnect the harness connector at the M30 Liftgate Latch.

- Test for less than 2 ohms in the control circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, test or replace the M30 Liftgate Latch.

- If the M30 Liftgate Latch activates

- Test or replace the KR95A Liftgate Unlatch Relay.

Component Testing

Liftgate Latch

- Ignition OFF, disconnect the harness connector at the M30 Liftgate Latch.

- Install a 10 A fused jumper wire between the control terminal 3 and 12 V. Install a jumper wire between the ground terminal 1 and ground.

- Verify the M30 Liftgate Latch activates

- If the M30 Liftgate Latch does not activate

Replace the M30 Liftgate Latch.

- If the M30 Liftgate Latch does activate.

- All OK

Liftgate Release Switch

- Ignition OFF, disconnect the harness connector at the S46B Liftgate Unlatch Switch.

- Test for infinite resistance between the signal terminal 1 and the ground terminal 2 with the switch in the open position.

- If less than infinite resistance

Replace the S46B Liftgate Unlatch Switch.

- If infinite resistance

- Test for less than 3 ohms between the signal terminal 1 and the ground terminal 2 with the switch in the closed position.

- If 3 ohms or greater

Replace the S46B Liftgate Unlatch Switch.

- If less than 3 ohms

- All OK

Relay Test

- Ignition OFF, disconnect the KR95A Liftgate Unlatch Relay.

- Test for 60-200 ohms between terminals 85 and 86.

- If less than 60 or greater than 200

Replace the KR95A Liftgate Unlatch Relay.

- If between 60-200 ohms

- Test for infinite resistance between the terminals listed below:

- 30 and 86

- 30 and 87

- 30 and 85

- 85 and 87

- If less than infinite resistance

Replace the KR95A Liftgate Unlatch Relay.

- If infinite resistance

- Install a 3 A fused jumper wire between relay terminal 85 and 12 V. Install a jumper wire between relay terminal 86 and ground.

- Test for less than 2 ohms between terminals 30 and 87.

- If 2 ohms or greater

Replace the KR95A Liftgate Unlatch Relay.

- If less than 2 ohms

- All OK

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Relay Replacement (Within an Electrical Center) , Relay Replacement (Attached to Wire Harness)

- Liftgate Release Switch Replacement

- Liftgate Latch Replacement

- Control Module References for BCM replacement, programming and setup

Door ajar indicator malfunction

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach

- Diagnostic Procedure Instructions provides an overview of each diagnostic category

Diagnostic Fault Information

.jpg)

Circuit/System Description

If the vehicle is equipped with power windows without the express features or with manual crank windows, the body control module (BCM) will provide a 12 V signal to each door ajar switch via the door ajar switch signal circuit. The door ajar switches are normally open when the door is fully closed. When a door is opened, the door ajar switch contacts close providing a path to ground. The instrument cluster receives a serial data message from the BCM indicating the door ajar status, the instrument cluster will then display the door ajar icon.

If the vehicle is equipped with express power windows, the window motors or the window switches each provide a 12 V signal to their respective door ajar switch signal circuits. The door ajar switches are integral to each door latch assembly. When a door is opened, the normally open door ajar switch closes. With the door ajar switch closed, ground is provided to the door ajar switch signal circuit and the voltage within the signal circuit drops. The window motor or the window switch will detect the voltage drop and will send a serial data message to the body control module which will then send a message to the instrument cluster to command the door ajar icon.

Reference Information

Schematic Reference

Door Lock/Indicator Schematics (Encore), Door Lock/Indicator Schematics (Encore)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Description and Operation

Door Ajar Indicator Description and Operation

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Verification

- Ignition ON.

- Verify the appropriate scan tool Door Ajar Switch parameter changes between Inactive and Active when opening and closing the driver door, the passenger door, the left rear door and right rear door.

- If any parameter does not change

Refer to Circuit/System Testing - Door Ajar Malfunction.

- If all the parameters change

- Verify the scan tool Rear Closure Ajar Switch parameter changes between Inactive and Active when opening and closing the liftgate.

- If the parameter does not change

Refer to Circuit/System Testing - Liftgate Ajar Malfunction.

- If the parameter changes

- All OK.

Circuit/System Testing

Door Ajar Malfunction

- Ignition OFF and all vehicle systems OFF, disconnect the harness connector at the appropriate A23 Door Latch Assembly. It may take up to 2 minutes for all vehicle systems to power down.

- Test for less than 10 ohms between the ground circuit terminal listed below and ground.

- A23D Door Latch Assembly-Driver - ground circuit terminal 8

- A23P Door Latch Assembly-Passenger - ground circuit terminal 3

- A23LR Door Latch Assembly-Left Rear - ground circuit terminal 8

- A23RR Door Latch Assembly-Right Rear - ground circuit terminal 3

- If 10 ohms or greater

- Ignition OFF.

- Test for less than 2 ohms in the ground circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, repair the open/high resistance in the ground connection.

- If less than 10 ohms

- Ignition ON.

- Verify the appropriate scan tool Door Ajar Switch parameter is Inactive.

- If not Inactive

- Ignition OFF, disconnect the harness connector at the appropriate component listed below:

- M74D Window Motor-Driver (AXG)

- S79D Window Switch-Driver (AEC)

- M74P Window Motor-Passenger (AEF)

- S79P Window Switch-Passenger (AED)

- M74LR Window Motor-Left Rear (AER)

- S79LR Window Switch-Left Rear (AEQ)

- M74RR Window Motor-Right Rear (AER)

- S79RR Window Switch-Right Rear (AEQ)

- K9 Body Control Module (A55, A66, A33 or crank windows)

- Test for infinite resistance between the signal circuit terminal listed below and ground.

- A23D Door Latch Assembly-Driver - signal circuit terminal 6

- A23P Door Latch Assembly-Passenger - signal circuit terminal 1

- A23LR Door Latch Assembly-Left Rear - signal circuit terminal 6

- A23RR Door Latch Assembly-Right Rear - signal circuit terminal 1

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance, replace the appropriate component.

- If Inactive

- Install a 3 A fused jumper wire between the signal circuit terminal listed below and ground.

- A23D Door Latch Assembly-Driver - signal circuit terminal 6

- A23P Door Latch Assembly-Passenger - signal circuit terminal 1

- A23LR Door Latch Assembly-Left Rear - signal circuit terminal 6

- A23RR Door Latch Assembly-Right Rear - signal circuit terminal 1

- Verify the scan tool Door Ajar Switch parameter is Active.

- If not Active

- Ignition OFF, remove the fused jumper wire, disconnect the harness connector at the appropriate component listed below, ignition ON.

- M74D Window Motor-Driver (AXG)

- S79D Window Switch-Driver (AEC)

- M74P Window Motor-Passenger (AEF)

- S79P Window Switch-Passenger (AED)

- M74LR Window Motor-Left Rear (AER)

- S79LR Window Switch-Left Rear (AEQ)

- M74RR Window Motor-Right Rear (AER)

- S79RR Window Switch-Right Rear (AEQ)

- K9 Body Control Module (A55, A66, A33 or crank windows)

- Test for less than 1 V between the signal circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V

- Test for less than 2 ohms in the signal circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the appropriate component.

- If Active

- Test or replace the A23 Door Latch Assembly.

Liftgate Ajar Switch

- Ignition OFF and all vehicle systems OFF, disconnect the harness connector at the M30 Liftgate Latch. It may take up to 2 minutes for all vehicle systems to power down.

- Test for less than 10 ohms between the ground circuit terminal 1 and ground.

If not Inactive

- Ignition OFF, disconnect the harness connector at the K9 Body Control Module.

- Test for infinite resistance between the signal circuit terminal 2 and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance, replace the K9 Body Control Module.

- If Inactive

- Install a 3 A fused jumper wire between the signal circuit terminal 2 and ground circuit terminal 1.

- Verify the scan tool Rear Closure Ajar Switch parameter is Active.

- If not Active

- Ignition OFF, remove the fused jumper wire, disconnect the harness connector at the K9 Body Control Module, ignition ON.

- Test for less than 1 V between the signal circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V

- Test for less than 2 ohms in the signal circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K9 Body Control Module.

- If Active

- Test or replace the M30 Liftgate Latch.

Component Testing

- Ignition OFF, disconnect the harness connector at the appropriate A23 Door Latch Assembly.

- Test for infinite resistance between the terminals listed below with the switch in the open position.

- A23D Door Latch Assembly-Driver - signal terminal 6 and ground terminal 8

- A23P Door Latch Assembly-Passenger - signal terminal 1 and ground terminal 3

- \A23LR Door Latch Assembly-Left Rear - signal terminal 6 and ground terminal 8

- A23RR Door Latch Assembly-Right Rear - signal terminal 1 and ground terminal 3

- If less than infinite resistance

Replace the A23 Door Latch Assembly.

- If infinite resistance

- Test for less than 3 ohms between the terminals listed below with the switch in the closed position.

- A23D Door Latch Assembly-Driver - signal terminal 6 and ground terminal 8

- A23P Door Latch Assembly-Passenger - signal terminal 1 and ground terminal 3

- A23LR Door Latch Assembly-Left Rear - signal terminal 6 and ground terminal 8

- A23RR Door Latch Assembly-Right Rear - signal terminal 1 and ground terminal 3

- If 3 ohms or greater

Replace the A23 Door Latch Assembly.

- If less than 3 ohms

- All OK

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Front Side Door Latch Replacement

- Rear Side Door Latch Replacement

- Front Side Door Window Switch Replacement (Driver Side, Encore) , Front Side Door Window Switch Replacement (Passenger Side, Encore) , Front Side Door Window Switch Replacement (Driver Side, Encore) , Front Side Door Window Switch Replacement (Passenger Side, Encore)

- Rear Side Door Window Switch Replacement

- Front Side Door Window Regulator Motor Replacement

- Rear Side Door Window Regulator Motor Replacement

- Liftgate Latch Replacement

- Control Module References for body control module replacement, programming and setup

Power door child lock malfunction

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

Diagnostic Fault Information

.jpg)

Circuit/System Description

The child door lockout switch on the front floor console controls the child locks on the rear doors. The lockout switch is an input to the body control module which controls the child security lock disable relay. When the body control module detects a voltage drop on the child door lockout signal circuit, it will apply voltage to the child security lock disable relay coil, this will energize the relay and the contact within the relay will then direct the voltage to lock the left rear and right rear child locks and then isolate them from the normal door lock system to prevent the rear doors from being opened by using the interior rear door handles. The body control module will then provide a ground for the lockout indicator causing the indicator to illuminate to notify the driver that the child door lockout system has been activated. If the body control module detects a fault in the child door lockout system, it will command the lockout indicator to flash ON and OFF for 30 seconds.

Reference Information

Schematic Reference

Door Lock/Indicator Schematics (Encore), Door Lock/Indicator Schematics (Encore)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Description and Operation

Power Door Locks Description and Operation

Electrical Information Reference

- Testing for Intermittent Conditions and Poor Connections

- Circuit Testing

- Wiring Repairs

- Connector Repairs

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Verification

- Ignition ON.

- Verify both interior rear door handles do not open the rear doors when commanding the Child Security Lock Motors ON with a scan tool.

- If both interior rear door handles open the rear doors

Refer to Circuit/System Testing - Security Lockout Inoperative.

- If a single interior rear door handle opens the rear door

Refer to Circuit/System Testing - Single Door Security Lockout Malfunction.

- If both interior door handles do not open the rear doors

- Verify both interior rear door handles will open the rear doors when commanding the Child Security Lock Motors OFF with a scan tool.

- If both interior rear door handles do not open the rear doors

Refer to Circuit/System Testing - Security Lockout Inoperative.

- If a single interior rear door handle does not open the rear door

Refer to Circuit/System Testing - Single Door Security Lockout Malfunction

- If both interior door handles open the rear doors

- Verify the scan tool Left Right Rear Child Security Lock Switch and Right Rear Child Security Lock Switch parameters changes from Inactive to Active when pressing the child lockout switch.

- If the parameters do not change

Refer to Circuit/System Testing - Lockout Switch Inoperative.

- If the parameters changes

- Verify the child lockout indicator turns ON and OFF when pressing the child lockout switch.

- If the child lockout indicator is always ON or always OFF

Refer to Circuit/System Testing - Lockout Indicator Malfunction.

- If the child lockout indicator turns ON and turns OFF

- All OK.

Circuit/System Testing

Security Lockout Inoperative

- Ignition OFF and all vehicle systems OFF, disconnect the X2 harness connector at the X50A Fuse Block- Underhood. It may take up to 2 minutes for all vehicle systems to power down.

- Test for less than 10 ohms between the ground circuit terminal C5 and ground.

- If 10 ohms or greater

- Ignition OFF.

- Test for less than 2 ohms in the ground circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, repair the open/high resistance in the ground connection.

- If less than 10 ohms

- Ignition OFF, connect the X2 harness connector at the X50A Fuse Block-Underhood. Disconnect the X4 harness connector at the K9 Body Control Module, ignition ON.

- Verify that a test lamp does not illuminate between the control circuit terminal 8 and ground.

- If the test lamp illuminates

- Ignition OFF, disconnect the X2 harness connector at the X50A Fuse Block-Underhood.

- Test for less than 1 V between the K9 Body Control Module control circuit terminal 8 X4 and ground

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V, replace the X50A Fuse Block-Underhood.

- If the test lamp is not illuminated

- Connect a 3A fused jumper wire between the control circuit terminal 8 and B+.

- Listen for an audible click from the X50A Fuse Block-Underhood as the KR113 Child Security Lock Disable Relay activates.

- If the KR113 Child Security Lock Disable Relay does not activate

- Ignition OFF, remove the jumper wire, disconnect the X2 harness connector at the X50A Fuse Block-Underhood.

- Test for infinite resistance between the K9 Body Control Module control circuit terminal 8 X4 and ground.

- If less than Infinite resistance, repair the short to ground on the circuit.

- If infinite resistance

- Test for less than 2 ohms in the control circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the X50A Fuse Block-Underhood.

- If the KR113 Child Security Lock Disable Relay activates

- Replace the K9 Body Control Module.

Single Door Security Lockout Malfunction

- Ignition OFF, disconnect the harness connector at the appropriate A23 Door Latch Assembly-Rear. Ignition ON.

- Verify the scan tool Rear Child Security Lock Switch parameter is Inactive.

- If not Inactive

- Ignition OFF, disconnect the harness connector at the K9 Body Control Module.

- Test for infinite resistance between the signal circuit terminal listed below and ground:

- A23LR Door Latch Assembly-Left Rear - signal circuit terminal 9

- A23RR Door Latch Assembly-Right Rear - signal circuit terminal 4

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance, replace the K9 Body Control Module.

- If Inactive

- Install a 3 A fused jumper wire between the signal circuit terminals listed below and ground:

- A23LR Door Latch Assembly-Left Rear - signal circuit terminal 9

- A23RR Door Latch Assembly-Right Rear - signal circuit terminal 4

- Verify the scan tool Rear Child Security Lock Switch parameter is Active.

- If not Active

- Ignition OFF, remove the 3 A fused jumper wire, disconnect the harness connector at the K9 Body Control Module, ignition ON.

- Test for less than 1 V between the signal circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V

- Test for less than 2 ohms in the signal circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K9 Body Control Module.

- If Active

- Connect a test lamp between control circuit terminals listed below:

- A23LR Door Latch Assembly-Left Rear - control circuit terminal 4 and control circuit terminal 7

- A23RR Door Latch Assembly-Right Rear - control circuit terminal 2 and control circuit terminal 9

- Verify the test lamp turns ON and OFF when commanding the Child Security Lock Motors Active and Inactive with a scan tool.

- If the test lamp remains OFF during either of the commands

- Ignition OFF, remove the test lamp, disconnect the harness connector at the K9 Body Control Module.

- Test for infinite resistance between each control circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance, replace the K9 Body Control Module.

- If the test lamp turns ON during each of the commands

- Test or replace the A23 Door Latch Assembly-Rear.

Lockout Switch Inoperative

- Ignition OFF and all vehicle systems OFF, disconnect the harness connector at the S48E Multifunction Switch-Center Console. It may take up to 2 minutes for all vehicle systems to power down.

- Test for less than 10 ohms between the ground circuit terminal 9 and ground.

- If 10 ohms or greater

- Ignition OFF.

- Test for less than 2 ohms in the ground circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, repair the open/high resistance in the ground connection.

- If less than 10 ohms

- Ignition ON.

- Test for greater than 10 V between the signal circuit terminal 3 and ground.

- If 10 V or less

- Ignition OFF, disconnect the harness connector at the K9 Body Control Module.

- Test for infinite resistance between the signal circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- Test for less than 2 ohms in the signal circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K9 Body Control Module.

- If greater than 10 V

- Test or replace the S48E Multifunction Switch-Center Console.

Lockout Indicator Malfunction

- Ignition OFF, disconnect the harness connector at the S48E Multifunction

Switch-Center Console.

Ignition ON

- Verify a test lamp illuminates between the control circuit terminal 8 and ground.

- If the test lamp does not illuminate

- Ignition OFF, remove the test lamp, disconnect the harness connector at the K9 Body Control Module.

- Test for infinite resistance between the control circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance

- Test for less than 2 ohms in the control circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K9 Body Control Module.

- If the test lamp illuminates

- Connect a test lamp between the control circuit terminal 2 and B+ and install a 3A fused at the signal circuit terminal 3.

- Verify the test lamp turns ON and OFF each time the 3A fused jumper wire is connected to ground.

- If the test lamp is always OFF

- Ignition OFF, remove the test lamp, disconnect the harness connector at the K9 Body Control Module, ignition ON.

- Test for less than 1 V between the control circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V

- Ignition OFF.

- Test for less than 2 ohms in the control circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K9 Body Control Module.

- If the test lamp is always ON

- Ignition OFF, remove the test lamp, disconnect the harness connector at the K9 Body Control Module.

- Test for infinite resistance between the control circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance, replace the K9 Body Control Module.

- If the test lamp turns ON and OFF

- Test or replace the S48E Multifunction Switch-Center Console.

Component Testing

Child Security Lockout Switch Test

- Ignition OFF, disconnect the harness connector at the S48E Multifunction Switch-Center Console.

- Test for infinite resistance between the signal terminal 3 and the ground terminal 9 with the switch in the open position.

- If less than infinite resistance

Replace the S48E Multifunction Switch-Center Console.

- If infinite resistance

- Test for less than 3ohms between the signal terminal 3 and the ground terminal 9 with the switch in the closed position.

- If 3 ohms or greater

Replace the S48E Multifunction Switch-Center Console.

- If less than 3 ohms

- All OK

Door Latch Test

- Ignition OFF, disconnect the harness connector at the appropriate A23 Door Latch Assembly-Rear.

- Install a 30 A fused jumper wire between one of the control terminals and 12 V. Momentarily install a jumper wire between the other control terminal and ground. Reverse the jumper wires at least two times, the A23 Door Latch Assembly-Rear should perform the LOCK and UNLOCK functions.

- If the function does not perform the LOCK and UNLOCK function

Replace the A23 Door Latch Assembly-Rear.

- If the function performs the LOCK and UNLOCK function

- All OK

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Rear Side Door Latch Replacement

- Instrument Panel Multifunction Switch Replacement (Encore)

- Front Compartment Fuse Block Replacement

- Control Module References body control module replacement, programming and setup

Power door locks malfunction

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

Diagnostic Fault Information

.jpg)

Circuit/System Description

The body control module (BCM) powers the reversible door latch assemblies by providing battery positive voltage and ground to the appropriate lock and unlock control circuits of the door latch assemblies. The lock and unlock control circuits of the rear doors and passenger door latch assemblies are all connected together.