Buick Encore: Diagnostic information and procedures

DTC P0601, P0603, P0604, OR P062F: Control module memory

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptors

NOTE: DTCs P0601, P0603, P0604 or P062F could set in other control modules. Verify the DTCs are set in the transmission control module (TCM).

DTC P0601

Control Module Read Only Memory Performance

DTC P0603

Control Module Long Term Memory Reset

DTC P0604

Control Module Random Access Memory Performance

DTC P062F

Control Module Long Term Memory Performance

Circuit/System Description

This is an internal fault detection of the transmission control module (TCM), which is part of the control solenoid valve assembly. This fault is handled inside the TCM and no external circuits are involved.

Conditions for Running the DTC

P0601 or P0604

Runs continuously when TCM is powered up.

P0603

One time at TCM power up.

P062F

One time at TCM power down.

Conditions for Setting the DTC

P0601

TCM has detected a read only memory (ROM) checksum error 5 times.

P0603

TCM has detected a non-volatile memory checksum error at TCM powerup.

P0604

TCM has detected a random access memory (RAM) test error 5 times.

P062F

TCM has detected a non-volatile memory error during power-down.

Action Taken When the DTC Sets

- P0601, P0603, P0604, and P062F are Type A DTCs.

- TCM commands maximum line pressure.

- TCM forces the torque converter clutch (TCC) OFF.

- TCM inhibits TCC engagement.

- TCM freezes transmission adaptive functions.

- TCM commands the high side driver OFF.

- TCM defaults the transmission to 4th gear and reverse.

- Torque management is enabled.

- TCM inhibits neutral idle.

- TCM inhibits Tap Up/Down function.

- TCM inhibits manual shifting of forward gears.

Conditions for Clearing the DTC

P0601, P0603, P0604, and P062F are Type A DTCs.

Reference Information

Schematic Reference

Automatic Transmission Controls Schematics (Encore, MH8 or MHB) , Automatic Transmission Controls Schematics (Encore, MH8 or MHB)

- Connector End View Reference

- WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

- Inline Harness Connector End Views (Encore) , Inline Harness Connector End Views (Encore)

Description and Operation

- Electronic Component Description

- Transmission Component and System Description

- Transmission General Description

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

DTC Type Reference

Powertrain Diagnostic Trouble Code (DTC) Type Definitions (LUV) , Powertrain Diagnostic Trouble Code (DTC) Type Definitions (2H0)

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Verification

CAUTION: Before programming a control module, the following must be observed, or control module damage may occur:

- The TIS terminal, MDI, and/or scan tool must have the latest software.

- The vehicle battery must be fully charged. The battery voltage should be between 12-14 volts.

- The TIS terminal, MDI, and/or scan tool connections must be secure.

- A battery charger must NOT be connected to the battery when programming a control module.

- Ignition OFF and all vehicle systems OFF. It may take up to 2 min for all vehicle systems to power down.

- Ignition ON.

- Verify that DTC P0601, P0603, P0604, or P062F is not set.

If any of the DTCs are set

Replace the Q8 Control Solenoid Valve Assembly.

If none of the DTCs are set

- Operate the vehicle within the Conditions for Running the DTC. You may also operate the vehicle within the conditions that you observed from the Freeze Frame/Failure Records data.

- Verify the DTC does not set.

If the DTC sets

Replace the Q8 Control Solenoid Valve Assembly.

If the DTC does not set

- All OK.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Perform the Transmission Adaptive Values Learn following all transmission repairs

- Control Module References for Control Solenoid Valve Assembly replacement, programming and setup

DTC P0634

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptor

DTC P0634

Control Module Overtemperature

Circuit/System Description

The transmission control module (TCM) temperature sensor is located inside of the control solenoid valve assembly which has no serviceable components. The TCM monitors the TCM temperature sensor for over temperature protection.

Conditions for Running the DTC

- DTC P0634 is not set.

- TCM temperature is between 0-240ºC (32-464ºF) for 0.25 s.

- Ignition voltage is 9-32 V.

- DTC runs continuously when above conditions are met.

Conditions for Setting the DTC

Condition 1

TCM has detected an internal temperature condition of 144ºC (291ºF) or greater for 5 s.

Condition 2

Ignition voltage is 18 V or greater and the TCM temperature is 50ºC (122ºF) or greater for 2 s.

Action Taken When the DTC Sets

- P0634 is a Type A DTC.

- TCM limits the transmission to 4th gear and reverse.

- TCM inhibits Tap Up/Down function.

- TCM inhibits manual shifting of forward gears.

- TCM enables torque management.

- TCM shuts down.

- TCM commands maximum line pressure.

Conditions for Clearing the DTC

P0634 is a Type A DTC.

Diagnostic Aids

During a road test, the TCM temperature should steadily increase to a normal operating temperature, and then stabilize.

Reference Information

Schematic Reference

Automatic Transmission Controls Schematics (Encore, MH8 or MHB) , Automatic Transmission Controls Schematics (Encore, MH8 or MHB)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Description and Operation

- Electronic Component Description

- Transmission Component and System Description

- Transmission General Description

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

DTC Type Reference

Powertrain Diagnostic Trouble Code (DTC) Type Definitions (LUV) , Powertrain Diagnostic Trouble Code (DTC) Type Definitions (2H0)

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Verification

- Ignition ON.

- Verify the scan tool Engine Coolant Temperature parameter was less than 125ºC (257ºF) when DTC set by reviewing the scan tool Freeze Frame/Failure Records.

If 125ºC (257ºF) or greater

Refer to Engine Overheating .

If less than 125ºC (257ºF)

- Verify the scan tool TCM Temperature parameter is less than 146ºC (295ºF).

If 146ºC (295ºF) or greater

Replace the Q8 Control Solenoid Valve assembly.

If less than 146ºC (295ºF)

- Verify the transmission fluid level and condition is correct. Refer to Transmission Fluid Level and Condition Check.

- If the transmission fluid level and condition is not correct

Repair as necessary.

If the transmission fluid level and condition is correct

- Clear the TCM DTCs with a scan tool.

- Operate the vehicle until normal engine temperature is reached.

- Verify the scan tool Transmission Fluid Temperature parameter is less than 140ºC (284ºF).

If 140ºC (284ºF) or greater

- Ignition OFF.

- Verify the conditions listed below do not exist:

- Obstructions to the airflow to the radiator or transmission

- Radiator damage

- Transmission cooler damage

- Transmission cooler pipe kinked or damaged

If a condition exists, repair or replace as necessary.

If none of the conditions exist, refer to Transmission Fluid Cooler Flushing and Flow Test .

If less than 140ºC (284ºF)

- Operate the vehicle within the Conditions for Running the DTC. You may also operate the vehicle within the conditions that you observed from the Freeze Frame/Failure Records data.

- Verify the DTC does not set.

If the DTC sets

Replace the Q8 Control Solenoid Valve Assembly.

If the DTC does not set

- All OK.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Perform the Transmission Adaptive Values Learn following all transmission repairs

- Transmission Fluid Cooler Hose/Pipe Quick-Connect Fitting Disconnection and Connection

- Transmission Fluid Cooler Inlet Pipe Replacement

- Transmission Fluid Cooler Outlet Pipe Replacement

- Control Module References for Control Solenoid Valve Assembly replacement, programming and setup

DTC P0658 OR P0659

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptors

DTC P0658

Actuator High Control Circuit Group 1 Low Voltage

DTC P0659

Actuator High Control Circuit Group 1 High Voltage

Circuit/System Description

The transmission control module (TCM) high side driver 1 is located inside the control solenoid valve assembly which has no serviceable components. The high side driver 1 provides power to the pressure control solenoid valves and shift solenoid valves.

Conditions for Running the DTC

P0658

- DTC P0658 is not set.

- High side driver 1 is enabled.

- Runs continuously when above conditions are met.

P0659

- DTC P0659 is not set.

- Runs one time when ignition transitions from OFF to ON.

Conditions for Setting the DTC

P0658

TCM detects an internal open or short to ground in the high side driver 1 circuit for 1 s.

P0659

TCM detects an internal short to voltage on the high side driver 1 circuit for 1 s.

Action Taken When the DTC Sets

P0658

- P0658 is a Type A DTC.

- TCM turns the high side driver OFF.

- TCM commands all solenoids OFF.

- TCM commands the TCC OFF.

- TCM commands maximum line pressure.

- TCM freezes transmission adaptive functions.

- TCM inhibits neutral idle.

- TCM inhibits the Tap Up/Tap Down function.

- TCM inhibits manual shifting of forward gears.

- TCM defaults the transmission to 4th gear and reverse.

- TCM enables torque management.

P0659

P0659 is a Type C DTC.

Conditions for Clearing the DTC

- P0658 is a Type A DTC.

- P0659 is a Type C DTC.

Reference Information

Schematic Reference

Automatic Transmission Controls Schematics (Encore, MH8 or MHB) , Automatic Transmission Controls Schematics (Encore, MH8 or MHB)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Description and Operation

- Electronic Component Description

- Transmission Component and System Description

- Transmission General Description

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

DTC Type Reference

Powertrain Diagnostic Trouble Code (DTC) Type Definitions (LUV) , Powertrain Diagnostic Trouble Code (DTC) Type Definitions (2H0)

Scan Tool Reference

Control Module References for scan tool information

Special Tools

DT-48616-10 Adapter Harness

For equivalent regional tools, refer to Special Tools .

Circuit/System Verification

- Ignition ON.

- Verify the scan tool High Side Driver 1 parameter displays ON.

If ON is not displayed

Refer to Circuit/System Testing.

If ON is displayed

- Engine Running and the gear selector lever in the Park position.

- Verify the scan tool parameters listed below do not display Malfunction:

- High Side Driver 1 Circuit Low Voltage Test Status

- High Side Driver 1 Circuit Open Test Status

- High Side Driver 1 Circuit High Voltage Test Status

If Malfunction is displayed

Refer to Circuit/System Testing.

If Malfunction is not displayed

- Operate the vehicle within the Conditions for Running the DTC. You may also operate the vehicle within the conditions that you observed from the Freeze Frame/Failure Records data.

- Verify the DTC does not set.

If the DTC sets

Refer to Circuit/System Testing.

If the DTC does not set

- All OK.

Circuit/System Testing

NOTE: You must perform the Circuit/System Verification first.

- Ignition OFF, remove the Q8 Control Solenoid Valve Assembly.

- Verify the Q8 Control Solenoid Valve Assembly is not contaminated with any debris. Refer to Control Solenoid Valve and Transmission Control Module Assembly Inspection.

If contaminated

Repair as necessary.

If not contaminated

- Verify the resistance is within the specified range for each solenoid listed in the Control Solenoid Valve and Transmission Control Module Assembly Inspection.

If the resistance is not within range

Replace the Q8 Control Solenoid Valve Assembly.

If the resistance is within range

- Place the Q8 Control Solenoid Valve Assembly on a clean work surface near the transmission assembly.

- Connect the DT-48616-10 adapter harness between the vehicle harness connector, and the Q8 Control Solenoid Valve Assembly connector. Ignition ON.

- Verify the scan tool parameters listed below do not display Malfunction:

- High Side Driver 1 Circuit Low Voltage Test Status

- High Side Driver 1 Circuit Open Test Status

- High Side Driver 1 Circuit High Voltage Test Status

If Malfunction is displayed

Replace the Q8 Control Solenoid Valve Assembly.

If Malfunction is not displayed

- All OK.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Perform the Transmission Adaptive Values Learn following all transmission repairs

- Control Module References - for Control Solenoid Valve Assembly replacement, programming and setup

DTC P0667, P0668, OR P0669

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptors

DTC P0667

Control Module Temperature Sensor Performance

DTC P0668

Control Module Temperature Sensor Circuit Low Voltage

DTC P0669

Control Module Temperature Sensor Circuit High Voltage

Circuit/System Description

The transmission control module (TCM) temperature sensor is located inside of the control solenoid valve assembly which has no serviceable components. The TCM temperature sensor provides the temperature of the TCM. This temperature reading is used in various shifting and diagnostic routines in the TCM software. This fault is handled inside the TCM and no external circuits are involved.

Conditions for Running the DTC

P0667

- DTC P0101, P0102, P0103, P0106, P0107, P0108, P0171, P0172, P0174, P0175, P0201, P0202, P0203, P0204, P0205, P0206, P0207, P0208, P0300, P0301, P0302, P0303, P0304, P0305, P0306, P0307, P0308, P0401, P042E, P0658, P0667, P0668, P0669, P06AD, P06AE, P0712, P0713, P0716, P0717, P0722, P0723, P0962, P0963, P0966, P0967, P0970, P0971, P215C, P2720, P2721, P2729, or P2730 is not set.

- Engine torque signal is valid.

- Ignition voltage is 9-32 V.

- Engine speed is 400-7,500 RPM for 5 s.

- Throttle position signal is valid.

- Runs continuously when above conditions are met.

P0668

- DTC P0668 is not set.

- Ignition voltage is 9-32 V.

- Engine speed is 400-7,500 RPM for 5 s.

- Runs continuously when above conditions are met.

P0669

- DTC P0669, P0716, P0717, P0722, or P0723 is not set.

- Ignition voltage is 9-32 V.

- Engine speed is 400-7,500 RPM for 5 s.

- Runs continuously when above conditions are met.

Conditions for Setting the DTC

P0667

- TCM detects a 20-50ºC (36-90ºF) or greater difference between the transmission fluid temperature and TCM substrate temperature, which depends on the average of the transmission fluid temperature, TCM substrate temperature, and TCM power up temperature.

- TCM detects a 8-10ºC (14-18ºF) or greater difference between the TCM power up temperature and TCM substrate temperature, which depends on the average of the transmission fluid temperature, TCM substrate temperature, and TCM power up temperature.

- Above conditions have to be met for 5 min within a 6 min period.

P0668

TCM internal temperature is 254ºC (489ºF) or greater for 1 min.

P0669

TCM internal temperature is -254ºC (-425ºF) or less for 1 min.

Action Taken When the DTC Sets

- P0667, P0668, and P0669 are Type B DTCs.

- TCM defaults the TCM substrate temperature to a calculated temperature based on the TCM power up temperature.

Conditions for Clearing the DTC

P0667, P0668, and P0669 are Type B DTCs.

Diagnostic Aids

The TCM temperature sensor is located inside of the control solenoid valve assembly and its output should resemble that of the transmission fluid temperature sensor output. During a road test, the TCM temperature should steadily increase to a normal operating temperature, and then stabilize.

Reference Information

Schematic Reference

Automatic Transmission Controls Schematics (Encore, MH8 or MHB) , Automatic Transmission Controls Schematics (Encore, MH8 or MHB)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

- Inline Harness Connector End Views (Encore) , Inline Harness Connector End Views (Encore)

Description and Operation

- Electronic Component Description

- Transmission Component and System Description

- Transmission General Description

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

DTC Type Reference

Powertrain Diagnostic Trouble Code (DTC) Type Definitions (LUV) , Powertrain Diagnostic Trouble Code (DTC) Type Definitions (2H0)

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Verification

- Ignition ON.

- Verify the scan tool TCM Temperature parameter is between -254 and +254ºC (-425 and +489ºF).

If not between -254 and +254ºC (-425 and +489ºF)

Replace the Q8 Control Solenoid Valve Assembly.

If between -254 and +254ºC (-425 and +489ºF)

- Verify the scan tool TCM Temperature parameter increases greater than 2ºC (3.6ºF) after operating the vehicle at 64 km/h (40 mph) for 10 min.

If the temperature does not increase greater than 2ºC (3.6ºF)

Replace the Q8 Control Solenoid Valve Assembly.

If the temperature increases greater than 2ºC (3.6ºF)

- Verify the scan tool Transmission Fluid Temperature and TCM Temperature parameters are within 20ºC (36ºF) of each other.

If the temperatures are not within 20ºC (36ºF)

Replace the Q8 Control Solenoid Valve Assembly.

If the temperatures are within 20ºC (36ºF)

- Operate the vehicle within the Conditions for Running the DTC. You may also operate the vehicle within the conditions that you observed from the Freeze Frame/Failure Records data.

- Verify the DTC does not set.

If the DTC sets

Replace the Q8 Control Solenoid Valve Assembly.

If the DTC does not set

- All OK.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Perform the Transmission Adaptive Values Learn following all transmission repairs

- Control Module References - for Control Solenoid Valve Assembly replacement, programming and setup

DTC P06AC, P06AD, OR P06AE

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptors

DTC P06AC

Control Module Power Up Temperature Sensor Performance

DTC P06AD

Control Module Power Up Temperature Sensor Circuit Low Voltage

DTC P06AE

Control Module Power Up Temperature Sensor Circuit High Voltage

Circuit/System Description

The transmission control module (TCM) power up temperature sensor is located inside of the Control Solenoid Valve Assembly which has no serviceable components. The TCM power up temperature sensor provides the temperature of the TCM when the TCM power is on. This temperature reading is used in various shifting and diagnostic routines in the TCM software. This fault is handled inside the TCM and no external circuits are involved.

Conditions for Running the DTC

P06AC

- DTC P0101, P0102, P0103, P0106, P0107, P0108, P0171, P0172, P0174, P0175, P0201, P0202, P0203, P0204, P0205, P0206, P0207, P0208, P0300, P0301, P0302, P0303, P0304, P0305, P0306, P0307, P0308, P0401, P042E, P0658, P0668, P0669, P06AC, P06AD, P06AE, P0712, P0713, P0716, P0717, P0722, P0723, P0962, P0963, P0966, P0967, P0970, P0971, P215C, P2720, P2721, P2729, or P2730 is not set.

- Throttle position signal is valid.

- Engine speed is 400-7,500 RPM for 5 s.

- Ignition voltage is 9-32 V.

- Engine torque signal is valid.

- DTC runs continuously when the above conditions are met.

P06AD

- DTC P06AD, P0716, P0717, P0722, or P0723 is not set.

- Engine speed is 400-7,500 RPM for 5 s.

- Ignition voltage is 9-32 V.

- DTC runs continuously when the above conditions are met.

P06AE

- DTC P06AE is not set.

- Engine speed is 400-7,500 RPM for 5 s.

- Ignition voltage is 9-32 V.

- DTC runs continuously when the above conditions are met.

Conditions for Setting the DTC

P06AC

- TCM detects a 20-50ºC (36-90ºF), or greater difference between the transmission fluid temperature and TCM power up temperature, which depends on the average of transmission fluid temperature, TCM substrate temperature, and TCM power up temperature.

- TCM detects an 8-10ºC (14-18ºF), or greater difference between the TCM substrate temperature and TCM power up temperature, which depends on the average of the transmission fluid temperature, TCM substrate temperature, and TCM power up temperature.

- Above conditions have to be met for 5 min within a 6 min period.

P06AD

TCM power up temperature is -254ºC (-425ºF) or less for 1 min.

P06AE

TCM power up temperature is 254ºC (489ºF) or greater for 1 min.

Action Taken When the DTC Sets

- P06AC, P06AD, and P06AE are Type B DTCs.

- TCM defaults the TCM power up temperature to a calculated temperature based on the TCM substrate temperature.

Conditions for Clearing the DTC

P06AC, P06AD, and P06AE are Type B DTCs.

Reference Information

Schematic Reference

Automatic Transmission Controls Schematics (Encore, MH8 or MHB) , Automatic Transmission Controls Schematics (Encore, MH8 or MHB)

Connector End View Reference

- Component Connector End Views (Encore) , Component Connector End Views (Encore)

- Inline Harness Connector End Views (Encore) , Inline Harness Connector End Views (Encore)

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

- Inline Harness Connector End Views (Encore) , Inline Harness Connector End Views (Encore)

Description and Operation

- Electronic Component Description

- Transmission Component and System Description

- Transmission General Description

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

DTC Type Reference

Powertrain Diagnostic Trouble Code (DTC) Type Definitions (LUV) , Powertrain Diagnostic Trouble Code (DTC) Type Definitions (2H0)

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Verification

- Ignition ON, clear the DTCs with a scan tool.

- Operate the vehicle at 64 km/h (40 mph) for 10 min.

- Verify DTC P06AC, P06AD, or P06AE is not set.

If any of the DTCs are set

Replace the Q8 Control Solenoid Valve Assembly.

If none of the DTCs are set

- Operate the vehicle within the Conditions for Running the DTC. You may also operate the vehicle within the conditions that you observed from the Freeze Frame/Failure Records data.

- Verify the DTC does not set.

If the DTC sets

Replace the Q8 Control Solenoid Valve Assembly.

If the DTC does not set

- All OK.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Perform the Transmission Adaptive Values Learn following all transmission repairs

- Control Module References - for Control Solenoid Valve Assembly replacement, programming and setup

DTC P0711-P0713

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category

DTC Descriptors

DTC P0711

Transmission Fluid Temperature Sensor Performance

DTC P0712

Transmission Fluid Temperature Sensor Circuit Low Voltage

DTC P0713

Transmission Fluid Temperature Sensor Circuit High Voltage

Circuit/System Description

The transmission fluid temperature sensor is located inside of the transmission control solenoid valve assembly which has no serviceable components. The transmission fluid temperature sensor provides transmission fluid temperature to the transmission control module (TCM). This fault is handled inside the TCM and no external circuits are involved.

Conditions for Running the DTC

P0711

- DTC P0101, P0102, P0103, P0106, P0107, P0108, P0171, P0172, P0174, P0175, P0201, P0202, P0203, P0204, P0205, P0206, P0207, P0208, P0300, P0301, P0302, P0303, P0304, P0305, P0306, P0307, P0308, P0401, P042E, P0658, P0668, P0669, P06AD, P06AE, P0711, P0712, P0713, P0716, P0717, P0722, P0723, P0962, P0963, P0966, P0967, P0970, P0971, P215C, P2720, P2721, P2729, or P2730 is not set.

- Engine speed is 400-7,500 RPM for 5 s.

- Ignition voltage is 9-32 V.

- Accelerator position signal is valid.

- Engine torque signal is valid.

- Brake torque is not active.

- DTC runs continuously when above conditions are met.

P0712

- DTC P0712, P0716, P0717, P0722, or P0723 is not set.

- Engine speed is 400-7,500 RPM for 5 s.

- Ignition voltage is 9-32 V.

- DTC runs continuously when above conditions are met.

P0713

- DTC P0713, P0716, P0717, P0722, or P0723 is not set.

- Engine speed is 400-7,500 RPM for 5 s.

- Ignition voltage is 9-32 V.

- DTC runs continuously when above conditions are met.

Conditions for Setting the DTC

P0711

- TCM detects a 20-50ºC (36-90ºF) or greater difference between the transmission fluid temperature and the TCM substrate temperature, which depends on the average of the transmission fluid temperature, TCM substrate temperature, and TCM power up temperature.

- TCM detects a 20-50ºC (36-90ºF) or greater difference between the transmission fluid temperature and the TCM power up temperature, which depends on the average of the transmission fluid temperature, TCM substrate temperature, and TCM power up temperature.

- Above conditions have to be met for 5 min within a 6 min period.

P0712

Transmission fluid temperature is 254ºC (489ºF) or greater for 1 min.

P0713

Transmission fluid temperature is -254ºC (-425ºF) or less for 1 min.

Action Taken When the DTC Sets

- P0711, P0712, and P0713 are Type B DTCs.

- TCM defaults to a calculated transmission fluid temperature based on the TCM temperature.

Conditions for Clearing the DTC

P0711, P0712, and P0713 are Type B DTCs.

Diagnostics Aids

The TCM temperature sensor is located inside of the control solenoid valve assembly and its output should resemble that of the transmission fluid temperature sensor's output. During a road test, the transmission fluid temperature should steadily increase to a normal operating temperature, and then stabilize.

Reference Information

Schematic Reference

Automatic Transmission Controls Schematics (Encore, MH8 or MHB) , Automatic Transmission Controls Schematics (Encore, MH8 or MHB)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

- Inline Harness Connector End Views (Encore) , Inline Harness Connector End Views (Encore)

Description and Operation

- Electronic Component Description

- Transmission Component and System Description

- Transmission General Description

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

DTC Type Reference

Powertrain Diagnostic Trouble Code (DTC) Type Definitions (LUV) , Powertrain Diagnostic Trouble Code (DTC) Type Definitions (2H0)

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Verification

- Engine idling at the normal operating temperature.

- Verify the scan tool Transmission Fluid Temperature parameter is between -254 and +254ºC (-425 and +489ºF).

If not between -254 and +254ºC (-425 and +489ºF)

Replace the Q8 Control Solenoid Valve Assembly.

If between -254 and +254ºC (-425 and +489ºF)

- Verify the scan tool Transmission Fluid Temperature parameter increases greater than 2ºC (3.6ºF) after operating the vehicle at 64 km/h (40 mph) for 10 min.

If the temperature does not increase greater than 2ºC (3.6ºF)

Replace the Q8 Control Solenoid Valve Assembly.

If the temperature increases greater than 2ºC (3.6ºF)

- Verify the scan tool Transmission Fluid Temperature and the TCM Temperature parameters are within 20ºC (36ºF).

If the temperatures are not within 20ºC (36ºF)

Replace the Q8 Control Solenoid Valve Assembly.

If the temperatures are within 20ºC (36ºF)

- Operate the vehicle within the Conditions for Running the DTC. You may also operate the vehicle within the conditions that you observed from the Freeze Frame/Failure Records data.

- Verify the DTC does not set.

If the DTC sets

Replace the Q8 Control Solenoid Valve Assembly.

If the DTC does not set

- All OK.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Perform the Transmission Adaptive Values Learn following all transmission repairs

- Control Module References for Control Solenoid Valve Assembly replacement, programming and setup

DTC P0716, P0717, P07BF, OR P07C0

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptors

DTC P0716

Input Speed Sensor Performance

DTC P0717

Input Speed Sensor Circuit No Signal

DTC P07BF

Input Speed Sensor Circuit Low Voltage

DTC P07C0

Input Speed Sensor Circuit High Voltage

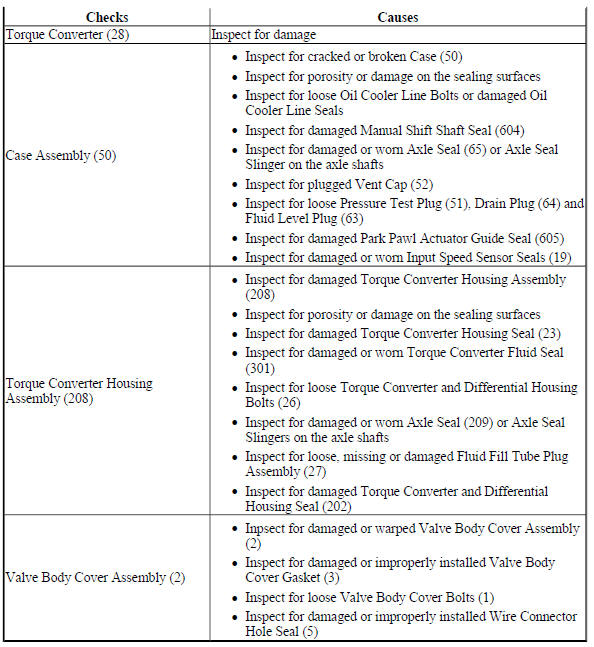

Diagnostic Fault Information

Typical Scan Tool Data

Transmission ISS

.jpg)

ISS/OSS Supply Voltage

.jpg)

Circuit/System Description

The input shaft speed (ISS) sensor is a hall-effect type sensor. The ISS sensor mounts to the inside of the automatic transmission case assembly and connects to the control solenoid valve assembly through a 2-wire harness and connector. The sensor faces a reluctor wheel, which is attached to the 4-5-6 clutch and 3-5-R clutch housing assembly. The sensor receives battery voltage on the ISS sensor supply voltage circuit from the transmission control module (TCM). As the 4-5-6 clutch and 3-5-R clutch housing rotates, the sensor produces a signal frequency based on the teeth of the reluctor wheel. This signal is transmitted through the ISS sensor signal circuit to the TCM. The TCM uses the ISS sensor signal to calculate input shaft speed to determine commanded line pressure, transmission shift patterns, torque converter clutch (TCC) slip speed and gear ratio

Conditions for Running the DTC

P0716

- DTC P0101, P0102, P0103, P0121, P0122, P0123, P0716, P0717, P0752, P0973, or P0974 is not set.

- Vehicle speed is 10 km/h (6 mph) or greater.

- Engine speed is 400-7,500 RPM for 5 s.

- Ignition voltage is 9-32 V.

- Engine torque signal is valid.

- Throttle position signal is valid.

- DTC runs continuously when above conditions are met.

P0717

- DTC P0717, P0722, or P0723 is not set.

- Engine speed is 400-7,500 RPM for 5 s.

- Ignition voltage is 9-32 V.

- Vehicle speed is 16 km/h (10 mph) or greater.

- Engine torque is 50 N.m (37 lb ft) or greater.

- DTC runs continuously when above conditions are met.

P07BF or P07C0

- Ignition voltage is 9-32 V.

- DTC runs continuously when above condition is met.

Conditions for Setting the DTC

P0716

TCM detects the transmission input shaft speed signal dropped greater than 1,350 RPM for 1 s.

P0717 - Condition 1

TCM detects the transmission input shaft speed signal is less than 33 RPM for 5 s.

P0717 - Condition 2

The TCM detects that P0722 set and the Transmission input speed is less than 1,000 RPM for 5 s.

P07BF

Transmission ISS sensor analog signal voltage is 0.25 V or less for 4 s.

P07C0

Transmission ISS sensor analog signal voltage is 4.75 volts or greater for 4 s.

Action Taken When the DTC Sets

- P0716, P0717, P07BF, and P07C0 are Type A DTCs.

- TCM freezes transmission adaptive functions.

- TCM forces TCC OFF.

- TCM inhibits Tap-Up/Tap-Down functions.

- TCM inhibits manual up, manual down shifts with the shift selector.

- TCM commands maximum line pressure.

- TCM enables torque management.

- TCM limits the transmission to reverse and 4th gear.

- TCM commands the high side driver off - P0716 only.

Conditions for Clearing the DTC

P0716, P0717, P07BF, and P07C0 are Type A DTCs.

Diagnostic Aids

- Inspect the ISS sensor harness and connector for metallic debris and the reluctor wheel for damage or misalignment.

- If the scan tool ISS/OSS Supply Voltage indicates out of range, the fault could also be caused by the transmission output shaft speed sensor.

Reference Information

Schematic Reference

Automatic Transmission Controls Schematics (Encore, MH8 or MHB) , Automatic Transmission Controls Schematics (Encore, MH8 or MHB)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

- Inline Harness Connector End Views (Encore) , Inline Harness Connector End Views (Encore)

Description and Operation

- Electronic Component Description

- Transmission Component and System Description

- Transmission General Description

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

DTC Type Reference

Powertrain Diagnostic Trouble Code (DTC) Type Definitions (LUV) , Powertrain Diagnostic Trouble Code (DTC) Type Definitions (2H0)

Scan Tool Reference

Control Module References for scan tool information

Special Tools

DT-48616-10 Adapter Harness

For equivalent regional tools, refer to Special Tools .

Circuit/System Verification

- Ignition ON.

- Verify the scan tool ISS/OSS Supply Voltage parameter displays OK.

If OK is not displayed

Refer to Circuit/System Testing.

If OK is displayed

- Engine idling, transmission in Park.

- Verify the scan tool Transmission ISS parameter changes without spikes or dropouts, while varying the engine speed.

If the Transmission ISS does not change with engine speed or has spikes or dropouts

Refer to Circuit/System Testing.

If the Transmission ISS changes with engine speed and there are no spikes or dropouts

- Operate the vehicle within the Conditions for Running the DTC. You may also operate the vehicle within the conditions that you observed from the Freeze Frame/Failure Records data.

- Verify the DTC does not set.

If the DTC sets

Refer to Circuit/System Testing.

If the DTC does not set

- All OK.

Circuit/System Testing

NOTE: You must perform the Circuit/System Verification first.

- Ignition OFF, remove the Q8 Control Solenoid Valve Assembly.

- Place the Q8 Control Solenoid Valve Assembly on a clean work surface near the transmission assembly.

- Connect the DT-48616-10 adapter harness between the vehicle harness connector and the Q8 Control Solenoid Valve Assembly connector. Ignition ON.

- Test for 11-13 V between the ISS 12 V circuit terminal B on the Q8 Control Solenoid Valve Assembly X3 connector and ground.

If not between 11-13 V

Replace the Q8 Control Solenoid Valve Assembly.

If between 11-13 V

- Verify the scan tool Transmission ISS parameter is between 495-505 RPM when performing the input shaft speed test. Refer to Control Solenoid Valve and Transmission Control Module Assembly Input Shaft Speed/Output Shaft Speed Input Test.

If not between 495-505 RPM

Replace the Q8 Control Solenoid Valve Assembly.

If between 495-505 RPM

- Verify there is no damage to the reluctor, which is attached to the 4-5-6 clutch and 3-5-R clutch housing assembly, or misalignment between the B14C Transmission Input Shaft Speed Sensor and reluctor.

If the reluctor is damaged or misaligned

Repair or replace as necessary.

If the reluctor is not damaged or misaligned

- Replace the B14C Transmission Input Shaft Speed Sensor.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Perform the Transmission Adaptive Values Learn following all transmission repairs

- Input and Output Speed Sensor Installation

- Input and Output Speed Sensor Removal

- Control Module References - for Control Solenoid Valve Assembly replacement, programming and setup

DTC P0722, P0723, P077C, OR P077D

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptors

DTC P0722

Output Speed Sensor Circuit No Signal

DTC P0723

Output Speed Sensor Circuit Intermittent

DTC P077C

Output Speed Sensor Circuit Low Voltage

DTC P077D

Output Speed Sensor Circuit High Voltage

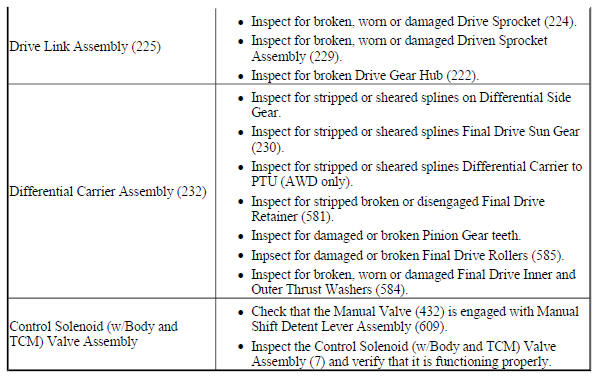

Diagnostic Fault Information

Typical Scan Tool Data

Transmission OSS

.jpg)

ISS/OSS Supply Voltage

.jpg)

Circuit/System Description

The output shaft speed (OSS) sensor is a hall-effect type sensor. The OSS sensor mounts to the automatic transmission case assembly and connects to the control solenoid valve assembly through a 2-wire harness and connector. The sensor faces the park gear teeth. The sensor receives battery voltage on the OSS sensor supply voltage circuit from the transmission control module (TCM). As the output shaft rotates, the sensor produces a signal frequency based on the park gear teeth. This signal is transmitted through the OSS sensor signal circuit to the TCM. The TCM uses the OSS sensor signal to calculate output shaft speed to determine commanded line pressure, transmission shift patterns, vehicle speed and gear ratio.

Conditions for Running the DTC

P0722

- DTC P0101, P0102, P0103, P0121, P0122, P0123, P0716, P0717, P0722, or P0723 is not set.

- Ignition voltage is 9-32 V.

- Engine speed is 400-7,500 RPM for 5 s.

- Engine torque signal is valid.

- Throttle position signal is valid.

- Transmission input speed is between 1,000-8,191 RPM.

- Calculated throttle position is 8% or greater.

- Engine torque is 30 N.m (22 lb ft) or greater.

- Transmission fluid temperature is -40ºC (-40ºF) or greater.

- DTC runs continuously when the above conditions are met.

P0723

- DTC P0101, P0102, P0103, P0121, P0122, P0123, P0723, P0973, P0974, P0976, or P0977 is not set.

- Ignition voltage is 9-32 V.

- Greater than 5 s since last transmission upshift or downshift.

- Engine speed is 400-7,500 RPM for 5 s.

- DTC runs continuously when the above conditions are met.

P077C

- DTC P077D is not set.

- Ignition voltage is 9-32 V.

- DTC runs continuously when the above conditions are met.

P077D

- DTC P077C is not set.

- Ignition voltage is 9-32 V.

- DTC runs continuously when the above conditions are met.

Conditions for Setting the DTC

P0722

Transmission output speed is 35 RPM or less for 5 s.

P0723

- Transmission output speed is 105 RPM or greater.

- TCM detects the transmission output shaft speed dropped greater than 1,000 RPM for 3 s.

P077C

Transmission OSS sensor analog signal voltage is 0.25 V or less for 4 s.

P077D

Transmission OSS sensor analog signal voltage is 4.75 V or greater for 4 s.

Action Taken When the DTC Sets

P0722

- P0722 is a Type A DTC.

- TCM freezes transmission adaptive functions.

- TCM commands maximum line pressure.

- TCM forces the torque converter clutch (TCC) OFF.

- TCM Enables torque management.

- TCM limits the transmission to reverse and 2nd gear.

- TCM inhibits neutral idle.

- TCM inhibits auto grade braking.

- TCM inhibits Tap-Up/Tap-Down functions.

- TCM inhibits manual up, manual down shifts with the shift selector.

- TCM commands 2nd gear when in a forward range and the output speed is less than 700 RPM, or neutral if the output speed is 700 RPM or greater.

P0723, P077C or P077D

- P0723, P077C, and P077D are Type A DTCs.

- TCM freezes transmission adaptive functions.

- TCM forces TCC OFF.

- TCM commands the high side driver OFF.

- TCM commands maximum line pressure.

- TCM enables torque management.

- TCM limits the transmission to reverse and 4th gear.

- TCM inhibits neutral idle.

- TCM inhibits Tap-Up/Tap-Down functions.

- TCM inhibits manual up, manual down shifts with the shift selector.

- TCM inhibits auto grade braking.

Conditions for Clearing the DIC/DTC

P0722, P0723, P077C, and P077D are Type A DTCs.

Diagnostic Aids

- Inspect the OSS senor, harness, and connector for metallic debris.

- Proper torque of the OSS sensor mounting bolt is critical to proper OSS sensor operation.

- If the scan tool ISS/OSS Supply Voltage indicates out of range, the fault could also be caused by the transmission input shaft speed sensor.

Reference Information

Schematic Reference

Automatic Transmission Controls Schematics (Encore, MH8 or MHB) , Automatic Transmission Controls Schematics (Encore, MH8 or MHB)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

- Inline Harness Connector End Views (Encore) , Inline Harness Connector End Views (Encore)

Description and Operation

- Electronic Component Description

- Transmission Component and System Description

- Transmission General Description

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

DTC Type Reference

Powertrain Diagnostic Trouble Code (DTC) Type Definitions (LUV) , Powertrain Diagnostic Trouble Code (DTC) Type Definitions (2H0)

Scan Tool Reference

Control Module References for scan tool information

Special Tools

DT-48616-10 Adapter Harness

For equivalent regional tools, refer to Special Tools .

Circuit/System Verification

- Ignition ON.

- Verify the scan tool ISS/OSS Supply Voltage parameter displays OK.

If OK is not displayed

Refer to Circuit/System Testing.

If OK is displayed

- Verify the scan tool Transmission OSS parameter changes with vehicle speed or does not drop out, while operating the vehicle at 16-32 km/h (10-20 mph).

If the Transmission OSS does not vary with vehicle speed or drops out

Refer to Circuit/System Testing

If the Transmission OSS varies with vehicle speed and does not drop out

- Operate the vehicle within the Conditions for Running the DTC. You may also operate the vehicle within the conditions that you observed from the Freeze Frame/Failure Records data.

- Verify the DTC does not set.

If the DTC sets

Refer to Circuit/System Testing.

If the DTC does not set

- All OK.

Circuit/System Testing

NOTE: You must perform the Circuit/System Verification first.

- Ignition OFF, remove the Q8 Control Solenoid Valve Assembly.

- Connect the DT-48616-10 adapter harness between the vehicle harness connector and the Q8 Control Solenoid Valve Assembly connector.

- Ignition ON.

- Test for 11-13 V between the OSS sensor voltage circuit terminal B at the Q8 Control Solenoid Valve Assembly X4 connector and ground.

If not between 11-13 V

Replace the Q8 Control Solenoid Valve Assembly.

If between 11-13 V

- Verify the scan tool Transmission OSS parameter is between 745-825 RPM when performing the output shaft speed test. Refer to Control Solenoid Valve and Transmission Control Module Assembly Input Shaft Speed/Output Shaft Speed Input Test.

If not between 745-825 RPM

Replace the Q8 Control Solenoid Valve Assembly.

If between 745-825 RPM

- Verify there is no damage to the park gear, or misalignment between the B14A Transmission Output Shaft Speed Sensor and the park gear.

If the park gear is damaged or misaligned

Repair or replace as necessary.

If the park gear is not damaged or misaligned

- Replace the B14A Transmission Output Shaft Speed Sensor.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Perform the Transmission Adaptive Values Learn following all transmission repairs

- Input and Output Speed Sensor Installation

- Input and Output Speed Sensor Removal

- Control Module References - for Control Solenoid Valve Assembly replacement, programming and setup

DTC P0741 OR P0742

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptors

NOTE: The DTCs listed below set due to a transmission hydraulic/mechanical condition. Perform the Circuit/System Verification and Circuit/System Testing to identify the cause.

DTC P0741

Torque Converter Clutch (TCC) System Stuck Off - Transmission Hydraulic/Mechanical Performance

DTC P0742

Torque Converter Clutch (TCC) System Stuck On - Transmission Hydraulic/Mechanical Performance

Circuit/System Description

The torque converter clutch (TCC) pressure control solenoid valve is part of the control solenoid valve assembly which has no serviceable components. The TCC pressure control solenoid valve is normally low and regulates transmission fluid pressure to the TCC regulator valve in the lower valve body and the TCC control valve in the fluid pump assembly. When vehicle operating conditions are appropriate to apply the torque converter clutch, the transmission control module (TCM) will increase TCC pressure control solenoid valve current flow, thereby increasing pressure to move the TCC control valve into the apply position. When the TCC is fully applied, the engine is coupled directly to the transmission. TCC release is accomplished by the TCM decreasing current flow to the TCC pressure control solenoid valves, which decreases the apply pressure and allows the TCC control valve to move to the release position. The TCM calculates torque converter slip speed based on the speed signal from the input shaft speed sensor and engine RPM provided by the engine control module (ECM).

Conditions for Running the DTC

P0741

- DTC P0101, P0102, P0103, P0106, P0107, P0108, P0171, P0172, P0174, P0175, P0201, P0202, P0203, P0204, P0205, P0206, P0207, P0208, P0300, P0301, P0302, P0303, P0304, P0305, P0306, P0307, P0308, P0401, P042E, P0716, P0717, P0722, P0723, P0741, P0742, P2763, or P2764 is not set.

- Engine speed is 400-7,500 RPM or greater for 5 s.

- Ignition voltage is 9-32 V.

- Transmission fluid temperature is between -6.7 to +130ºC (+20 to +266ºF).

- Throttle position is 8% or greater.

- Engine torque is 50 N.m (36 lb ft) or greater.

- Engine torque signal is valid.

- Throttle position signal is valid.

- TCM detects the transmission gear ratios listed below for the commanded gear when TCC is commanded ON:

- 2nd gear ratio is between 2.75-3.17.

- 3rd gear ratio is between 1.78-2.04.

- 4th gear ratio is between 1.35-1.55.

- 5th gear ratio is between 0.93-1.07.

- 6th gear ratio is between 0.70-0.80.

- DTC runs continuously when the above conditions are met.

P0742

- DTC P0101, P0102, P0103, P0106, P0107, P0108, P0171, P0172, P0174, P0175, P0201, P0202, P0203, P0204, P0205, P0206, P0207, P0208, P0300, P0301, P0302, P0303, P0304, P0305, P0306, P0307, P0308, P0401, P042E, P0716, P0717, P0722, P0723, P0741, P0742, P2763, or P2764 is not set.

- Engine speed is 400-7,500 RPM for 5 s.

- Ignition voltage is 9-32 V.

- Transmission fluid temperature is between 15-130ºC (59-266ºF).

- Calculated throttle position was 10% or greater and has not dropped below 2%.

- Engine torque signal is valid.

- Throttle position signal is valid.

- Engine torque is 60 N.m (44 lb ft) or greater.

- Vehicle speed greater than 1 km/h (0.6 mph).

- TCC is commanded OFF.

- Engine torque signal is valid.

- Throttle position signal is valid.

- DTC runs continuously when the above conditions are met.

Conditions for Setting the DTC

P0741

- TCC pressure command is 500 kPa (73 PSI) or greater for 2 s.

- TCM detects TCC slip is 130 RPM or greater for 5 s.

- The above conditions must occur 2 times.

P0742

TCM detects the TCC slip is between -50 and +13 RPM for 1 s when TCC is commanded OFF. This condition must occur 8 times.

Action Taken When the DTC Sets

P0741

- P0741 is a Type B DTC.

- TCM inhibits 6th gear.

- TCM initiates Hot Mode shift pattern.

- TCM commands the TCC OFF.

- P0742

- P0742 is a Type A DTC.

- TCM initiates Hot Mode shift pattern.

- TCM freezes transmission adaptive functions.

- TCM commands the TCC ON.

- TCM inhibits neutral idle.

Conditions for Clearing the DIC/DTC

- P0741 is a Type B DTC.

- P0742 is a Type A DTC.

Reference Information

Schematic Reference

Automatic Transmission Controls Schematics (Encore, MH8 or MHB) , Automatic Transmission Controls Schematics (Encore, MH8 or MHB)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Inline Harness Connector End Views (Encore) , Inline Harness Connector End Views (Encore)

Description and Operation

- Electronic Component Description

- Transmission Component and System Description

- Transmission General Description

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

DTC Type Reference

Powertrain Diagnostic Trouble Code (DTC) Type Definitions (LUV) , Powertrain Diagnostic Trouble Code (DTC) Type Definitions (2H0)

Scan Tool Reference

Control Module References for scan tool information

Special Tools

DT-48616 Solenoid Assembly Test Kit & Adapter Harness

For equivalent regional tools, refer to Special Tools .

Circuit/System Verification

- Ignition ON, engine OFF.

- Verify DTC P0716, P0717, P07BF, or P07C0 was not set by reviewing the scan tool TCM Failure Records.

If any of the DTCs were set

Refer to DTC P0716, P0717, P07BF, or P07C0.

If none of the DTCs were set

- Engine idling, transmission in Park, with parking brake applied and drive wheels chocked.

- Verify the transmission fluid level and condition is correct. Refer to Transmission Fluid Level and Condition Check.

If the transmission fluid level and condition is not correct

Repair as necessary.

If the transmission fluid level and condition is correct

- Ignition ON, clear the TCM DTCs with a scan tool.

- Verify DTC P0741 or P0742 does not set while performing a road test. Refer to Road Test.

If DTC P0741 or P0742 sets

Refer to Circuit/System Testing.

If DTC P0741 or P0742 does not set

- Operate the vehicle within the Conditions for Running the DTC. You may also operate the vehicle within the conditions that you observed from the Freeze Frame/Failure Records data.

- Verify the DTC does not set.

If the DTC sets

Refer to Circuit/System Testing.

If the pressure changes

- Verify the mechanical conditions listed below do not exist. Repair or replace as necessary.

P0741 Upper Valve Body

Release exhaust port/orifice plugged or blocked.

P0741 or P0742 - Upper Valve Body

Torque converter clutch regulator valve stuck/sticking - debris, binding, damaged valve, or scored bore.

P0741 - Channel Plate and Spacer Plate

Oil channels or orifices blocked by debris.

P0741 or P0742 - Fluid Pump Assembly

Torque converter clutch control valve stuck/sticking - debris, binding, damaged valve, or scored bore.

P0741 - Torque Converter

- Torque converter clutch delamination or material worn off.

- Converter bolts too long damaging the clutch apply surface.

- Damaged seal

P0741 - Support

Damaged seal.

P0741 or P0742 - A/Trans Case Cover (403)

- Pressure release blow-off not seating/sealing.

- Damaged spring.

P0741 - Turbine Shaft O-ring Seal

Cut or damaged.

P0741 or P0742 - Q8 Control Solenoid Valve Assembly

- Torque converter clutch pressure control solenoid stuck OFF or leaking.

- Torque converter clutch pressure control solenoid stuck ON.

- Control signal fluid supply leak due to valve body filter plate assembly cracked, or damaged gasket seal.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Perform the Transmission Adaptive Values Learn following all transmission repairs.

- Control Valve Body Assembly Removal

- Control Module References for Control Solenoid Valve Assembly replacement, programming and setup.

DTC P0751 OR P0752

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category

DTC Descriptors

NOTE: The DTCs listed below set due to a transmission hydraulic/mechanical condition. Perform the Circuit/System Verification and Circuit/System Testing to identify the cause.

DTC P0751

Shift Solenoid Valve 1 Performance - Stuck Off - Transmission Hydraulic/Mechanical Performance

DTC P0752

Shift Solenoid Valve 1 Performance - Stuck On - Transmission Hydraulic/Mechanical Performance

Circuit/System Description

Shift solenoid valve 1 is part of the control solenoid valve assembly, which has no serviceable components. The solenoid valve operates by the transmission control module (TCM) turning the low side driver ON or OFF.

When the shift solenoid valve 1 is commanded OFF, the plunger forces the metering ball against the actuator feed limit seat, blocking the flow and any existing pressure is exhausted through the exhaust port. When the shift solenoid valve 1 is commanded ON, the internal plunger moves, allowing the metering valve to move away from the actuator feed limit seat and against the exhaust seat, creating signal fluid pressure. The signal fluid pressure acts against the clutch select valve 2 to overcome the valve spring force, moving the valve to the apply position. Fluid pressure from the R1/4-5-6 regulator valve flows through clutch select valve 2 and is directed to either the low and reverse clutch or the 4-5-6 clutch, depending on the position of clutch select valve 2.

Conditions for Running the DTC

- DTC P0101, P0102, P0103, P0106, P0107, P0108, P0171, P0172, P0174, P0175, P0201, P0202, P0203, P0204, P0205, P0206, P0207, P0208, P0300, P0301, P0302, P0303, P0304, P0305, P0306, P0307, P0308, P0401, P042E, P0716, P0717, P0722, P0723, or P182E is not set.

- Transmission fluid temperature is -6.6ºC (20ºF) or greater.

- Engine speed is between 400-7,500 RPM for 5 s.

- Output shaft speed is 100 RPM or greater, or the throttle position is 0.5% or greater.

- Ignition voltage is 9-32 V.

- Shift is complete.

- Engine torque signal is valid.

- Throttle position signal is valid.

- High-Side driver is enabled.

- DTC runs continuously when above conditions are met.

Conditions for Setting the DTC

P0751

- Commanded gear is 1st.

- TCM detects gear ratio 1.37-1.52.

- Gearbox slip is 400 RPM or greater for 2 s.

- Conditions listed above have to occur 8 times.

P0752

- Commanded gear is 3rd.

- Transmission has achieved 1st or 2nd.

- Gear slip is 400 RPM or greater for 1.5 s.

- TCM commands 4th gear if above conditions exist and detects a gear ratio of 4.35-4.81 for 1.5 s.

- Conditions listed above have to occur 5 times.

Action Taken When the DTC Sets

P0751

- P0751 is a type B DTC.

- TCM inhibits 1st gear.

- TCM inhibits Neutral idle.

P0752

- P0752 is a type A DTC.

- TCM limits the transmission to 2nd range and reverse.

- TCM inhibits Tap Up/Down function.

- TCM inhibits manual shifting of forward gears.

- TCM inhibits auto grade braking.

- TCM disables neutral idle.

- TCM freezes adapts.

- TCM commands maximum line pressure.

- TCM commands 2nd gear if transmission is in a forward range and the output speed is less than 1350 RPM, or neutral if the output speed is 1350 RPM or greater.

Conditions for Clearing the DTC

- P0751 is a type B DTC.

- P0752 is a type A DTC.

Reference Information

Schematic Reference

Automatic Transmission Controls Schematics (Encore, MH8 or MHB) , Automatic Transmission Controls Schematics (Encore, MH8 or MHB)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

- Inline Harness Connector End Views (Encore) , Inline Harness Connector End Views (Encore)

Description and Operation

- Drive Range, First Gear Engine Braking (Gen 2/Hybrid)

- Drive Range, Third Gear (Gen 2/Hybrid)

- Electronic Component Description

- Transmission Component and System Description

- Transmission General Description

DTC Type Reference

Powertrain Diagnostic Trouble Code (DTC) Type Definitions (LUV) , Powertrain Diagnostic Trouble Code (DTC) Type Definitions (2H0)

Scan Tool Reference

Control Module References for scan tool information

Special Tools

DT-48616 Solenoid Assembly Test Kit & Adapter Harness

For equivalent regional tools, refer to Special Tools

Circuit/System Verification

NOTE: If other DTCs are set, diagnose those DTCs first.

- Ignition ON, engine OFF.

- Verify no other TCM DTCs are set using a scan tool.

If another DTC is set

Refer to Diagnostic Trouble Code (DTC) List - Vehicle .

If no other DTCs are set

- Engine idling at the normal operating temperature, transmission in Park, with parking brake applied and drive wheels chocked.

- Verify the transmission fluid level and condition is correct. Refer to Transmission Fluid Level and Condition Check.

If the transmission fluid level and condition is not correct

Repair as necessary.

If the transmission fluid level and condition is correct

- Ignition ON, clear the TCM DTCs with a scan tool.

- From a stop, accelerate to 72 km/h (45 mph) with the Calculated Throttle

Position greater than 15%.

Perform this test 8 times.

- Verify DTC P0751 or P0752 did not set.

If DTC P0751 or P0752 sets

Refer to Circuit/System Testing.

If DTC P0751 or P0752 does not set

- Operate the vehicle within the Conditions for Running the DTC. You may also operate the vehicle within the conditions that you observed from the Freeze Frame/Failure Records data.

- Verify the DTC does not set.

If the DTC sets

Refer to Circuit/System Testing.

If the DTC does not set

- All OK.

Circuit/System Testing

WARNING: Refer to Parking Brake and Drive Wheels Warning .

NOTE: You must perform the Circuit/System Verification first.

- Engine idling at the normal operating temperature.

- Verify the transmission line pressures are within the specified range. Refer to Line Pressure Check, and Solenoid Valve Pressure (Gen 2) .

If the pressures are not within range

Refer to Fluid Pressure High or Low.

If the pressures are within range

- Ignition OFF, remove the Q8 Control Solenoid Valve Assembly.

- Verify the pressure changes for all solenoids when performing the solenoid test. Refer to Control Solenoid Valve and Transmission Control Module Assembly Solenoid Performance Test.

If the pressure does not change

Replace the Q8 Control Solenoid Valve Assembly.

If the pressure changes

- Verify the mechanical conditions listed below do not exist. Repair or replace as necessary.

P0751 - Control Valve Body

- Clutch select valve bore plug undersized. Plug should be a valve fit in the bore.

- Check ball #1 missing, damaged/malformed.

- Seat for check ball #1 damaged or leaking.

P0751 or P0752 - Control Valve Body

- Clutch select valve stuck from debris, sediment, binding, or a scored bore.

- Low and reverse and 4-5-6 clutch regulator valve stuck or sticking from debris, sediment, binding, or a scored bore.

P0751 or P0752 - Channel Plate and Spacer Plate

Oil channels or orifices blocked by debris.

P0751 or P0752 - Q8 Control Solenoid Valve Assembly

- Not pressurizing due to shift solenoid valve 1 being stuck OFF or leaking.

- Pressure not exhausting due to shift solenoid valve 1 being stuck ON.

- Control signal fluid supply leak due to valve body filter plate assembly cracked, blocked, or damaged gasket seal.

P0752 Output Carrier Assembly

Output carrier pinion pins too high or too low.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Perform the Transmission Adaptive Values Learn following all transmission repairs

- Control Module References - for Control Solenoid Valve Assembly replacement, programming and setup

DTC P0776 OR P0777

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptors

NOTE: The DTCs listed below set due to a transmission hydraulic/mechanical condition. Perform the Circuit/System Verification and Circuit/System Testing to identify the cause.

DTC P0776

Pressure Control Solenoid Valve 2 Stuck Off - Transmission Hydraulic/Mechanical Performance

DTC P0777

Pressure Control Solenoid Valve 2 Stuck On - Transmission Hydraulic/Mechanical Performance

Circuit/System Description

Pressure control solenoid valve 2 is part of the control solenoid valve assembly, which has no serviceable components. Pressure control solenoid valve 2 regulates transmission fluid pressure to the 3-5-R regulator valve, which controls pressure to the 3-5-R clutch. The transmission control module (TCM) calculates gear ratio based on the speed signals from the input shaft speed sensor and the output shaft speed sensor. The TCM compares the expected transmission gear ratio to the calculated gear ratio for each commanded gear.

Conditions for Running the DTC

P0776

- DTC P0101, P0102, P0103, P0106, P0107, P0108, P0171, P0172, P0174, P0175, P0201, P0202, P0203, P0204, P0205, P0206, P0207, P0208, P0300, P0301, P0302, P0303, P0304, P0305, P0306, P0307, P0308, P0401, P042E, P0716, P0717, P0722, P0723, or P182E is not set.

- Engine speed is 400-7,500 RPM for 5 s.

- Ignition voltage is 9-32 V.

- Transmission fluid temperature is -6.7ºC (20ºF) or greater.

- Transmission output speed is 100 RPM or greater, or the throttle position is 0.5% or greater.

- Throttle position signal is valid.

- High side driver is enabled.

- Commanded range is reverse, 3rd gear or 5th gear.

- DTC runs continuously when the above conditions are met.

P0777

- DTC P0101, P0102, P0103, P0106, P0107, P0108, P0171, P0172, P0174, P0175, P0201, P0202, P0203, P0204, P0205, P0206, P0207, P0208, P0300, P0301, P0302, P0303, P0304, P0305, P0306, P0307, P0308, P0401, P042E, P0716, P0717, P0722, P0723, or P182E is not set.

- Engine speed is 400-7,500 RPM for 5 s.

- Ignition voltage is 9-32 V.

- Transmission fluid temperature is -6.7ºC (20ºF) or greater.

- Transmission output shaft speed is 100 RPM or greater, or the throttle position is 0.5% or greater.

- Throttle position signal is valid.

- High side driver is enabled.

- Throttle position is 10% or greater and the engine torque is 45 N.m (33 lb ft) or greater.

- DTC runs continuously during shift when the 3-5-R clutch is commanded OFF, until commanded range is attained.

Conditions for Setting the DTC

P0776 - Condition 1

- Commanded gear is 3rd.

- Gearbox slip of 400 RPM or greater is detected for 2.5 s.

- TCM commands 4th gear if the above conditions exist and detects a gear ratio of 1.37-1.52 for 3 s.

- Conditions listed above have to occur 2 times.

P0776 - Condition 2

- Commanded gear is 5th.

- Gearbox slip of 400 RPM or greater is detected for 3 s.

- TCM commands 6th gear if the above conditions exist and detects 6th gear ratio for 3.5 s.

- Conditions listed above have to occur 3 times.

P0777

- The TCM detects an incorrect off-going clutch gear ratio, or tie-up, when the 3-5-R clutch is commanded OFF for 1 s.

- The transmission input shaft speed is 400 RPM or less from the anticipated input shaft speed.

- The conditions listed above must occur 3 times.

Action Taken When the DTC Sets

P0776

- P0776 is a Type A DTC.

- TCM commands maximum line pressure.

- TCM freezes transmission adaptive functions.

- TCM inhibits TAP Up/TAP Down function.

- TCM inhibits manual shifting of forward gears.

- TCM inhibits powertrain braking.

- TCM inhibits auto grade braking.

- TCM inhibits neutral idle.

- TCM commands 2nd gear if the transmission is in a forward gear and the output speed is less than 700 RPM.

- TCM commands neutral if the output speed is 700 RPM or greater.

P0777

- P0777 is a Type A DTC.

- TCM commands maximum line pressure.

- TCM limits the transmission to reverse and 3rd gear.

- TCM freezes transmission adaptive functions.

- TCM inhibits TAP Up/TAP Down function.

- TCM inhibits manual shifting of forward gears.

- TCM inhibits neutral idle.

- TCM inhibits powertrain braking.

- TCM inhibits auto grade braking.

Conditions for Clearing the DTC

P0776 and P0777 are Type A DTCs.

Diagnostic Aids

Before performing a road test, configure and setup the scan tool for snapshot mode. This will allow you to display, monitor, and verify multiple transmission data parameters at one time, after the road test.

Reference Information

Schematic Reference

Automatic Transmission Controls Schematics (Encore, MH8 or MHB) , Automatic Transmission Controls Schematics (Encore, MH8 or MHB)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

- Inline Harness Connector End Views (Encore) , Inline Harness Connector End Views (Encore)

Description and Operation

- Drive Range, Third Gear (Gen 2/Hybrid)

- Drive Range - Fourth Gear (Gen 2/Hybrid)

- Drive Range, Fifth Gear (Gen 2/Hybrid)

- Electronic Component Description

- Transmission Component and System Description

- Transmission General Description

DTC Type Reference

Powertrain Diagnostic Trouble Code (DTC) Type Definitions (LUV) , Powertrain Diagnostic Trouble Code (DTC) Type Definitions (2H0)

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Verification

WARNING: Refer to Parking Brake and Drive Wheels Warning .

NOTE: If other DTCs are set, diagnose those DTCs first.

- Ignition ON.

- Verify DTC P0716, P0717, P0722, P0723, P077C, P077D, P07BF, or P07C0 was not set by reviewing the scan tool Freeze Frame/Failure Records data.

If any of the DTCs were set

Refer to Diagnostic Trouble Code (DTC) List - Vehicle .

If none of the DTCs were set

- Engine idling, transmission in Park, with parking brake applied and drive wheels chocked.

- Verify the transmission fluid level and condition is correct. Refer to Transmission Fluid Level and Condition Check.

If the transmission fluid level and condition is not correct

Repair as necessary.

If the transmission fluid level and condition is correct

- Ignition ON, clear the TCM DTCs with a scan tool.

- Verify DTC P0776 or P0777 does not set while performing a road test. Refer to Road Test.

If DTC P0776 or P0777 sets

Refer to Circuit/System Testing.

If DTC P0776 or P0777 does not set

- Operate the vehicle within the Conditions for Running the DTC. You may also operate the vehicle within the conditions that you observed from the Freeze Frame/Failure Records data.

- Verify the DTC does not set.

If the DTC sets

Refer to Circuit/System Testing.

If the DTC does not set

- All OK.

Circuit/System Testing

NOTE: You must perform the Circuit/System Verification first.

- Engine idling at the normal operating temperature.

- Verify the transmission line pressures are within the specified range. Refer to Line Pressure Check, and Solenoid Valve Pressure (Gen 2) .

If the pressures are not within range

Refer to Fluid Pressure High or Low.

If the pressures are within range

- Ignition OFF, remove the Q8 Control Solenoid Valve Assembly.

- Verify the pressure changes for all solenoids when performing the solenoid test. Refer to Control Solenoid Valve and Transmission Control Module Assembly Solenoid Performance Test.

If the pressure does not change

Replace the Q8 Control Solenoid Valve Assembly.

If the pressure changes

- Verify the mechanical conditions listed below do not exist. Repair or replace as necessary.

DTC P0776 or P0777 - Control Valve Body Assembly

- Actuator feed limit circuit supply fluid to solenoids restricted or not available - debris or sediment blockage.

- 3-5-R Regulator Valve stuck/sticking - debris, binding, damaged valve, or scored bore.

- Control valve body ball check valve not seating correctly - debris.

DTC P0776 - 3-5-R and 4-5-6 Clutch Housing Assembly

3-5-R clutch backing plate retaining ring not seated, causing clutch pack over-travel.

DTC P0776 or P0777 - Torque Converter (w/Fluid Pump) Housing Assembly

Fluid pump housing/gear damaged/scored

DTC P0776 - Channel Plate and Spacer Plate

Oil channels or orifices blocked by debris.

DTC P0776 or P0777 - Q8 Control Solenoid Valve Assembly

- Clutch Pressure Control Solenoid 2 stuck ON/OFF.

- O-ring seals leaking.

- Valve body filter plate assembly cracked, blocked, or damaged gasket seal.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Perform the Transmission Adaptive Values Learn following all transmission repairs

- Control Module References - for Control Solenoid Valve Assembly replacement, programming and setup

DTC P0796 OR P0797

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptors

NOTE: The DTCs listed below set due to a transmission hydraulic/mechanical condition. Perform the Circuit/System Verification and Circuit/System Testing to identify the cause.

DTC P0796

Pressure Control Solenoid Valve 3 Stuck Off - Transmission Hydraulic/Mechanical Performance

DTC P0797

Pressure Control Solenoid Valve 3 Stuck On - Transmission Hydraulic/Mechanical Performance

Circuit/System Description

Pressure control solenoid valve 3 is part of the control solenoid valve assembly, which has no serviceable components. Pressure control solenoid valve 3 regulates transmission fluid pressure to the R1/4-5-6 regulator valve which controls pressure to the reverse and low clutch and the 4-5-6 clutch. The transmission control module (TCM) calculates gear ratio based on the speed signals from the automatic transmission input shaft speed sensor and the output shaft speed sensor. The TCM compares the expected transmission gear ratio to the calculated gear ratio for each commanded gear.

Conditions for Running the DTC

P0796

- DTC P0101, P0102, P0103, P0106, P0107, P0108, P0171, P0172, P0174, P0175, P0201, P0202, P0203, P0204, P0205, P0206, P0207, P0208, P0300, P0301, P0302, P0303, P0304, P0305, P0306, P0307, P0308, P0401, P042E, P0716, P0717, P0722, P0723, or P182E is not set.

- Engine speed is 400-7,500 RPM for 5 s.

- Transmission output speed is 100 RPM or greater or the throttle position is 0.5% or greater.

- Ignition voltage is 9-32 V.

- Transmission fluid temperature is -6.7ºC (20ºF) or greater.

- High side driver is enabled.

- Throttle position signal is valid.

P0797