Buick Encore: Repair instructions - off vehicle

Repair instructions - off vehicle

.gif)

Fig. 1: Identifying Lift Plate & Holding Fixture

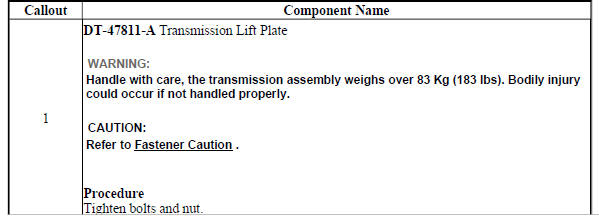

Lift Plate and Holding Fixture Installation

.jpg)

TORQUE CONVERTER REMOVAL

Fig. 2: View Of Torque Converter

Torque Converter Removal

.jpg)

CONTROL VALVE BODY ASSEMBLY REMOVAL

Control Valve Body Cover Removal

Fig. 3: View Of Control Valve Body Cover

Control Valve Body Cover Removal

.jpg)

Control Solenoid (With Body and TCM) Valve Assembly Removal

Fig. 4: View Of Control Solenoid (w/Body & TCM) Valve Assembly

Control Solenoid (With Body and TCM) Valve Assembly Removal

.jpg)

Control Valve Body Assembly Removal

Fig. 5: View Of Control Valve Body Assembly

Control Valve Body Assembly Removal

.jpg)

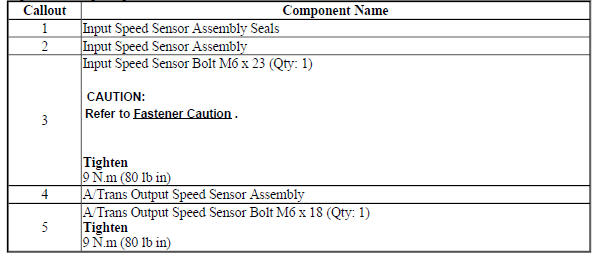

Input and output speed sensor removal

.gif)

Fig. 6: View Of Input & Output Speed Sensor

Input and Output Speed Sensor Removal

.jpg)

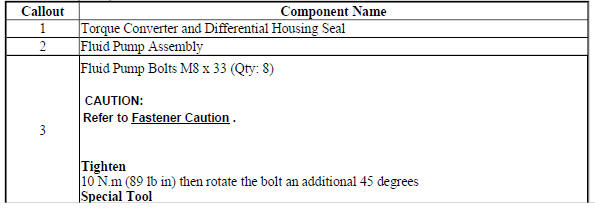

TORQUE CONVERTER HOUSING WITH FLUID PUMP ASSEMBLY REMOVAL (NON HYBRID)

Fig. 7: View Of Torque Converter Housing & Fluid Pump Assembly

Torque Converter Housing with Fluid Pump Assembly Removal (Non Hybrid)

.jpg)

DIFFERENTIAL CARRIER REMOVAL (6T40)

Fig. 8: View Of Front Differential Carrier Assembly

Differential Carrier Removal (6T40)

.jpg)

DRIVE AND DRIVEN SPROCKET, DRIVE LINK, AND PARK PAWL REMOVAL (6T40)

Fig. 9: View Of Drive and Driven Sprocket, Drive Link & Park Pawl

Drive and Driven Sprocket, Drive Link, and Park Pawl Removal (6T40)

.jpg)

.gif)

INTERNAL COMPONENTS REMOVAL

Fig. 10: View Of Transmission Internal Components

Internal Components Removal

.jpg)

.jpg)

2-6 CLUTCH PISTON REMOVAL

Fig. 11: View Of 2-6 Clutch Piston & Attached Components

2-6 Clutch Piston Removal

.jpg)

.jpg)

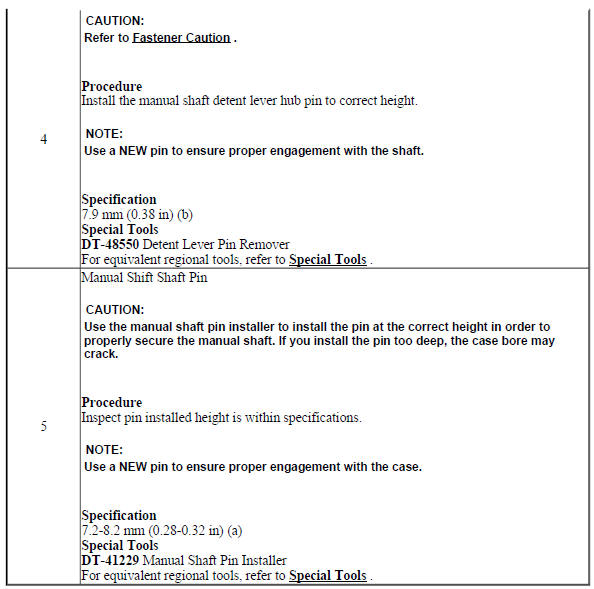

MANUAL SHIFT DETENT LEVER WITH SHAFT POSITION SWITCH ASSEMBLY AND PARK PAWL ACTUATOR REMOVAL

Manual Shaft Detent (w/Shift Position Switch) Lever Assembly Removal

Fig. 12: Identifying Manual Shaft Detent Lever Assembly

Manual Shaft Detent (w/Shift Position Switch) Lever Assembly Removal

.jpg)

.jpg)

Park Pawl Actuator Guide Removal

.gif)

Fig. 13: Identifying Park Pawl Actuator Guide Components

Park Pawl Actuator Guide Removal

.jpg)

.jpg)

Manual shift shaft seal removal

.gif)

Fig. 14: identifying Manual Shift Shaft Seal

Manual Shift Shaft Seal Removal

.jpg)

INPUT SHAFT SUPPORT REPLACEMENT (GEN 2)

.gif)

Fig. 15: Input Shaft Support Components (Gen 2)

Input Shaft Support Replacement (Gen 2)

.jpg)

3-5-REVERSE AND 4-5-6 CLUTCH FLUID SEAL RING REPLACEMENT (GEN 2)

Fig. 16: 3-5-Reverse and 4-5-6 Clutch Fluid Seal Ring (Gen 2)

3-5-Reverse and 4-5-6 Clutch Fluid Seal Ring Replacement (Gen 2)

.jpg)

.jpg)

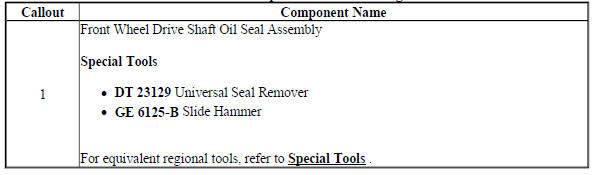

Front wheel drive shaft seal replacement - case side

.gif)

Fig. 17: View Of Case Side Front Wheel Drive Shaft Seal

Front Wheel Drive Shaft Seal Replacement - Case Side

.jpg)

TRANSMISSION CASE CLEANING AND INSPECTION

.gif)

Fig. 18: Cleaning & Inspecting Transmission Case

Transmission Case Cleaning and Inspection

.jpg)

.jpg)

MANUAL SHIFT DETENT LEVER WITH SHAFT POSITION SWITCH ASSEMBLY AND PARK PAWL ACTUATOR INSTALLATION

Park Pawl Actuator Guide Installation

.gif)

Fig. 19: View Of Park Pawl Actuator Guide & Seal

Park Pawl Actuator Guide Installation

.jpg)

.jpg)

Park Pawl Actuator Installation

.gif)

Fig. 20: Identifying Manual Shift Detent Lever with Shaft Position Switch

Assembly & Park Pawl Actuator

Park Pawl Actuator Installation

.jpg)

MANUAL SHIFT SHAFT SEAL INSTALLATION

Fig. 21: Identifying Manual Shift Shaft Seal

Manual Shift Shaft Seal Installation

.jpg)

2-6 CLUTCH PISTON INSTALLATION (6T40)

.gif)

Fig. 22: View Of 2-6 Clutch Piston Assembly

2-6 Clutch Piston Installation (6T40)

.jpg)

.jpg)

LOW AND REVERSE AND 1-2-3-4 CLUTCH HOUSING, LOW AND REVERSE CLUTCH ASSEMBLY, OUTPUT SUN GEAR, AND 2-6 CLUTCH PLATE DISASSEMBLE (GEN 2)

.gif)

Fig. 23: 1-2-3-4 Clutch Housing And Clutch Assembly Components

Low and Reverse and 1-2-3-4 Clutch Housing, Low and Reverse Clutch Assembly, Output Sun Gear, and 2-6 Clutch Plate Disassemble (Gen 2)

.jpg)

.jpg)

Input, reaction, and output carrier disassemble

.gif)

Fig. 24: Disassembled View Of Input, Reaction & Output Carrier

Courtesy of GENERAL MOTORS COMPANY

Input, Reaction, and Output Carrier Disassemble

.jpg)

3-5-REVERSE AND 4-5-6 CLUTCH HOUSING DISASSEMBLE (6T40 - GEN 2)

Turbine Shaft, Reluctor Wheel and Piston Removal

Fig. 25: Turbine Shaft, Reluctor Wheel And Piston

Turbine Shaft, Reluctor Wheel and Piston Removal

.jpg)

4-5-6 Clutch Plate Removal

.gif)

Fig. 26: 4-5-6 Clutch Plate Components

4-5-6 Clutch Plate Removal

.jpg)

4-5-6 Clutch Piston Removal

Fig. 27: 4-5-6 Clutch Piston Components

4-5-6 Clutch Piston Removal

.jpg)

.jpg)

Reluctor Wheel and Piston Removal

.gif)

Fig. 28: Disassembled View Of Reluctor Wheel & Piston

Reluctor Wheel and Piston Removal

.jpg)

.jpg)

3-5 Reverse Clutch Plate Removal

Fig. 29: 3-5 Reverse Clutch Plate Components

3-5 Reverse Clutch Plate Removal

.jpg)

.jpg)

3-5-REVERSE AND 4-5-6 CLUTCH HOUSING ASSEMBLE (6T40 - GEN 2)

4-5-6 Clutch Piston Installation

.gif)

Fig. 30: 4-5-6 Clutch Piston Components

4-5-6 Clutch Piston Installation

.jpg)

.jpg)

4-5-6 Clutch Fluid Dam Installation

.gif)

Fig. 31: 4-5-6 Clutch Fluid Dam

4-5-6 Clutch Fluid Dam Installation

.jpg)

.jpg)

3-5 Reverse Clutch Plates Installation

Fig. 32: 3-5 Reverse Clutch Plates

3-5 Reverse Clutch Plates Installation

.jpg)

Reluctor Wheel and Piston Installation

.gif)

Fig. 33: Exploded View Of Reluctor Wheel & Piston

Reluctor Wheel and Piston Installation

.jpg)

.jpg)

4-5-6 Clutch Plates Installation

.gif)

Fig. 34: 4-5-6 Clutch Plates

4-5-6 Clutch Plates Installation

.jpg)

Turbine Shaft Installation

Fig. 35: View Of Turbine Shaft

Turbine Shaft Installation

.jpg)

INPUT, REACTION, AND OUTPUT CARRIER ASSEMBLE (GEN 2)

Fig. 36: Input, Reaction, and Output Carrier Components (Gen 2)

Input, Reaction, and Output Carrier Assemble (Gen 2)

.jpg)

.jpg)

3-5-REVERSE AND 4-5-6 CLUTCH HOUSING, AND INPUT, REACTION, AND OUTPUT CARRIER INSTALLATION

Fig. 37: View Of 3-5-Reverse, 4-5-6 Clutch Housing, Input, Reaction & Output

Carrier Components

3-5-Reverse and 4-5-6 Clutch Housing, and Input, Reaction, and Output Carrier Installation

.jpg)

LOW AND REVERSE CLUTCH ASSEMBLY AND LOW AND REVERSE CLUTCH PLATE INSTALLATION

.gif)

Fig. 38: View Of Low and Reverse Clutch Assembly

Low and Reverse Clutch Assembly and Low and Reverse Clutch Plate Installation

.jpg)

.jpg)

Low and reverse and 1-2-3-4 clutch housing isassemble

Low and Reverse Clutch Piston Removal

.gif)

Fig. 39: View Of Low & Reverse Clutch Piston

Low and Reverse Clutch Piston Removal

.jpg)

.jpg)

1-2-3-4 Clutch Piston Removal

.gif)

Fig. 40: View Of 1-2-3-4 Clutch Piston

1-2-3-4 Clutch Piston Removal

.jpg)

LOW AND REVERSE AND 1-2-3-4 CLUTCH HOUSING CLEANING AND INSPECTION

.gif)

Fig. 41: Identifying Low and Reverse & 1-2-3-4 Clutch Housing

Low and Reverse and 1-2-3-4 Clutch Housing Cleaning and Inspection

.jpg)

LOW AND REVERSE AND 1-2-3-4 CLUTCH HOUSING ASSEMBLE

1-2-3-4 Clutch Piston Installation

.gif)

Fig. 42: View Of 1-2-3-4 Clutch Piston

1-2-3-4 Clutch Piston Installation

.jpg)

.jpg)

Low and Reverse Clutch Piston Installation

.gif)

Fig. 43: View Of Low & Reverse Clutch Piston

Low and Reverse Clutch Piston Installation

.jpg)

.jpg)

LOW AND REVERSE AND 1-2-3-4 CLUTCH HOUSING, AND 1-2-3-4 CLUTCH PLATE INSTALLATION (6T40)

.gif)

Fig. 44: View Of Low and Reverse & 1-2-3-4 Clutch Housing & Attached

Components

Low and Reverse and 1-2-3-4 Clutch Housing, and 1-2-3-4 Clutch Plate Installation (6T40)

.jpg)

Drive sprocket, driven sprocket, and drive link cleaning and inspection

Fig. 45: View Of Drive Sprocket, Driven Sprocket & Drive Link

Drive Sprocket, Driven Sprocket, and Drive Link Cleaning and Inspection

.jpg)

DRIVE AND DRIVEN SPROCKET, DRIVE LINK, AND PARK PAWL INSTALLATION (6T40)

.gif)

Fig. 46: View Of Drive Sprocket, Driven Sprocket & Park Paw

Drive and Driven Sprocket, Drive Link, and Park Pawl Installation (6T40)

.jpg)

.jpg)

FRONT DIFFERENTIAL CARRIER CLEANING AND INSPECTION

.gif)

Fig. 47: View Of Front Differential Carrier

Front Differential Carrier Cleaning and Inspection

.jpg)

.jpg)

FRONT DIFFERENTIAL CARRIER INSTALLATION (6T40)

.gif)

Fig. 48: View Of Front Differential Carrier Components

Front Differential Carrier Installation (6T40)

.jpg)

TRANSMISSION FLUID PUMP, FRONT DIFFERENTIAL CARRIER BAFFLE, AND FRONT DIFFERENTIAL RING GEAR REMOVAL (6T40)

Fig. 49: View Of Transmission Fluid Pump, Front Differential Carrier Baffle &

Components

Transmission Fluid Pump, Front Differential Carrier Baffle, and Front Differential Ring Gear Removal (6T40)

.jpg)

FRONT WHEEL DRIVE SHAFT SEAL REMOVAL - TORQUE CONVERTER HOUSING SIDE

Fig. 50: Front Wheel Drive Shaft Seal - Torque Converter Housing Side

Front Wheel Drive Shaft Seal Removal - Torque Converter Housing Side

FRONT DIFFERENTIAL CARRIER BEARING REMOVAL (AWD)

Fig. 51: Front Differential Carrier Bearing (AWD)

Front Differential Carrier Bearing Removal (AWD)

.jpg)

FRONT DIFFERENTIAL CARRIER BEARING INSTALLATION (AWD)

.gif)

Fig. 52: Front Differential Carrier Bearing (AWD)

Front Differential Carrier Bearing Installation (AWD)

.jpg)

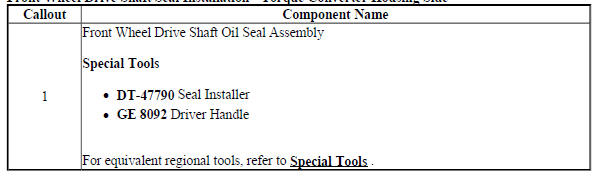

FRONT WHEEL DRIVE SHAFT SEAL INSTALLATION - TORQUE CONVERTER HOUSING SIDE

Fig. 53: Front Wheel Drive Shaft Seal - Torque Converter Housing Side

Front Wheel Drive Shaft Seal Installation - Torque Converter Housing Side

TORQUE CONVERTER HOUSING CLEANING AND INSPECTION

Fig. 54: Identifying Torque Converter Housing Inspection Areas

Torque Converter Housing Cleaning and Inspection

.jpg)

TRANSMISSION FLUID PUMP DISASSEMBLE (6T40)

Fluid Filter Assembly and Torque Converter Fluid Seal Disassemble

.gif)

Fig. 55: View Of Fluid Filter Assembly & Torque Converter Fluid Seal

Fluid Filter Assembly and Torque Converter Fluid Seal Disassembl

.jpg)

.jpg)

Fluid Pump Disassemble

.gif)

Fig. 56: Transmission Fluid Pump & Components

Fluid Pump Disassemble

.jpg)

.jpg)

FLUID PUMP SELECTIVE MEASUREMENT

.gif)

Fig. 57: Measuring Fluid Pump Components

Fluid Pump Selective Measurement

.jpg)

.jpg)

TRANSMISSION FLUID PUMP ASSEMBLE (6T40)

Fluid Pump w/Valve Trains Assemble

.gif)

Fig. 58: Fluid Pump W/Valve Trains Assembly

Fluid Pump w/Valve Trains Assemble

.jpg)

Torque Converter Fluid Seal and Fluid Filter Assembly Assemble

Fig. 59: View Of Torque Converter Fluid Seal & Fluid Filter Assembly

Torque Converter Fluid Seal and Fluid Filter Assembly Assemble

.jpg)

TRANSMISSION FLUID PUMP, FRONT DIFFERENTIAL CARRIER BAFFLE, AND FRONT DIFFERENTIAL RING GEAR INSTALLATION (6T40)

Fig. 60: Identifying Transmission Fluid Pump, Front Differential Carrier

Baffle & Front Differential Ring Gear

Transmission Fluid Pump, Front Differential Carrier Baffle, and Front Differential Ring Gear Installation (6T40)

.jpg)

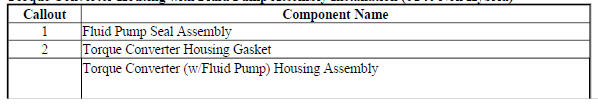

TORQUE CONVERTER HOUSING WITH FLUID PUMP ASSEMBLY INSTALLATION (6T40 NON HYBRID)

Fig. 61: Identifying Torque Converter Housing & Fluid Pump Assembly

Torque Converter Housing with Fluid Pump Assembly Installation (6T40 Non Hybrid)

.jpg)

INPUT AND OUTPUT SPEED SENSOR INSTALLATION

Fig. 62: Identifying Input & Output Speed Sensor

Input and Output Speed Sensor Installation

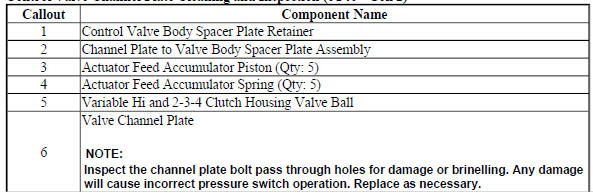

CONTROL VALVE BODY ASSEMBLY DISASSEMBLE (GEN 2)

.gif)

Fig. 63: Control Valve Body (Gen 2)

Control Valve Body Assembly Disassemble (Gen 2)

.jpg)

CONTROL VALVE BODY CLEANING AND INSPECTION (GEN 2)

.gif)

Fig. 64: Control Valve Body Cleaning and Inspection (Gen 2)

Control Valve Body Cleaning and Inspection (Gen 2)

.jpg)

.jpg)

CONTROL VALVE CHANNEL PLATE CLEANING AND INSPECTION (6T40 - GEN 2)

.gif)

Fig. 65: Control Valve Channel Plate Cleaning and Inspection

Control Valve Channel Plate Cleaning and Inspection (6T40 - Gen 2)

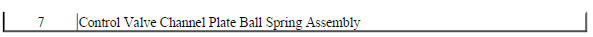

Control valve body assembly assemble (gen 2)

Fig. 66: Control Valve Body And Components

Control Valve Body Assembly Assemble (Gen 2)

.jpg)

CONTROL VALVE BODY ASSEMBLY INSTALLATION

Fig. 67: View Of Control Valve Body Assembly Attachments

Control Valve Body Assembly Installation

.jpg)

.jpg)

CONTROL SOLENOID VALVE AND TRANSMISSION CONTROL MODULE ASSEMBLY INSTALLATION

.gif)

Fig. 68: Identifying Control Solenoid Valve & TCM Bolt Tightening Sequence

Control Solenoid Valve and Transmission Control Module Assembly Installation

.jpg)

.jpg)

CONTROL VALVE BODY COVER INSTALLATION

.gif)

Fig. 69: Identifying Control Valve Body Cover Bolt Tightening Sequence

Control Valve Body Cover Installation

.jpg)

.jpg)

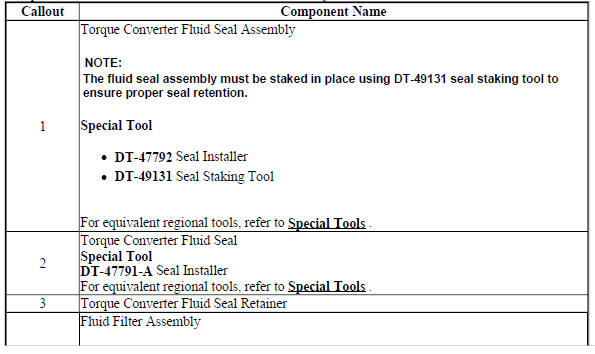

TORQUE CONVERTER FLUID SEAL REPLACEMENT

.gif)

Fig. 70: View Of Torque Converter Fluid Seal & Retainer

Torque Converter Fluid Seal Replacement

.jpg)

.jpg)

TORQUE CONVERTER INSTALLATION

.gif)

Fig. 71: View Of Torque Converter

Torque Converter Installation

.jpg)

.jpg)

LIFT PLATE AND HOLDING FIXTURE REMOVAL

.gif)

Fig. 72: Identifying Lift Plate & Holding Fixture

Lift Plate and Holding Fixture Removal

.jpg)

.jpg)