Buick Encore: Engine controls and fuel - 1.4l - Diagnostic information and procedures

DTC P0010, P0013, OR P2088-P2091

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category

DTC Descriptor

DTC P0010

Intake Camshaft Position Actuator Solenoid Valve Control Circuit

DTC P0013

Exhaust Camshaft Position Actuator Solenoid Valve Control Circuit

DTC P2088

Intake Camshaft Position Actuator Solenoid Valve Control Circuit High Voltage

DTC P2089

Intake Camshaft Position Actuator Solenoid Valve Control Circuit High Voltage

DTC P2090

Exhaust Camshaft Position Actuator Solenoid Valve Control Circuit Low Voltage

DTC P2091

Exhaust Camshaft Position Actuator Solenoid Valve Control Circuit High Voltage

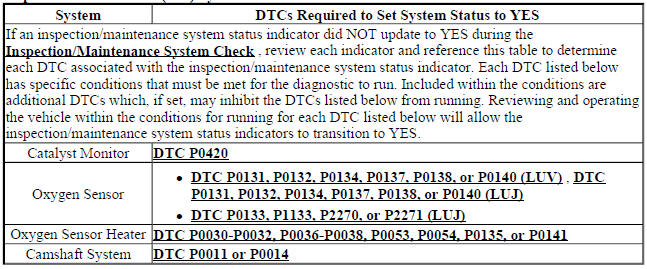

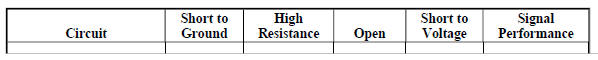

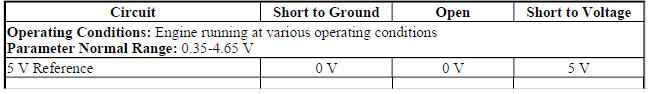

Diagnostic Fault Information

Circuit/System Description

The camshaft position actuator system enables the Engine Control Module (ECM) to change the timing of the camshafts while the engine is operating. The Camshaft Position Actuator Solenoid Valve signal from the ECM is pulse width modulated (PWM). The ECM controls the Camshaft Position Actuator Solenoid Valve duty cycle by controlling the amount of solenoid valve On time. The Camshaft Position Actuator Solenoid Valve controls the advance or the retard of each camshaft. The Camshaft Position Actuator Solenoid Valve controls the oil flow that applies the pressure to advance or retard the camshafts.

The ECM controls the Camshaft Position Actuator Solenoid Valve by suppling a 12 V pulse width modulated (PWM) signal. The ECM supplies a ground to the low reference circuit.

Conditions for Running the DTC

- The ignition voltage is greater than 11 V

- The ignition switch is in the crank or run position.

- The ECM has commanded the Camshaft Position Actuator Solenoid Valve On.

- The DTCs run continuously once the above conditions are met.

Conditions for Setting the DTC

The ECM detects that the commanded state of the driver and the actual state of the control circuit do not match for greater than 5 s.

Action Taken When the DTC Sets

DTCs P0010, P0013, P2088, P2089, P2090 and P2091 are type B DTCs.

Conditions for Clearing the DTC

DTCs P0010, P0013, P2088, P2089, P2090 and P2091 are type B DTCs.

Diagnostic Aids

If the condition is intermittent, move the related harnesses and connectors, with the engine operating, while monitoring the scan tool Circuit Test Status parameters for the component. The Circuit Test Status parameters change from OK or Not Run to Malfunction if there is a condition with the circuit or a connection.

Reference Information

Schematic Reference

Engine Controls Schematics (Encore) , Engine Controls Schematics (Encore)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Component View Reference

Powertrain Component Views

Description and Operation

Camshaft Actuator System Description

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

DTC Type Reference

Powertrain Diagnostic Trouble Code (DTC) Type Definitions (LUV) , Powertrain Diagnostic Trouble Code (DTC) Type Definitions (2H0)

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Verification

NOTE: If a crankshaft or camshaft position sensor DTC is set, the Camshaft Position Actuator output control will not function.

- Ignition On.

- Verify DTC P0335, P0336, P0340, or P0341 is not set.

- If any of the DTCs are set

Refer to Diagnostic Trouble Code (DTC) List - Vehicle .

- If none of the DTCs are set

- Engine idling, command the Camshaft Position Actuator to 10º while observing the following control circuit status parameters with a scan tool:

- Exhaust or Intake Camshaft Position Actuator Solenoid Valve Control Circuit Open Test Status

- Exhaust or Intake Camshaft Position Actuator Solenoid Valve Control Circuit Low Voltage Test Status

- Intake or Exhaust Camshaft Position Actuator Solenoid Valve Control Circuit High Voltage Test Status

- If Malfunction is displayed

Refer to Circuit/System Testing

- If Malfunction is not displayed

- Operate the vehicle within the Conditions for Running the DTC. You may also operate the vehicle within the conditions that you observed from the Freeze Frame/Failure Records data.

- Verify the DTC does not set.

- If the DTC sets

Refer to Circuit/System Testing.

- If the DTC does not set

- All OK.

Circuit/System Testing

- Ignition Off and all vehicle systems Off, disconnect the appropriate harness connector at the camshaft position actuator solenoid valve. It may take up to 2 minutes for all vehicle systems to power down.

- Test for less than 5 ohms between the low reference circuit terminal 1 and ground.

- If 5 ohms or greater

- Ignition Off, disconnect the harness connector at the K20 Engine Control Module.

- Test for less than 2 ohms in the low reference circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K20 Engine Control Module.

- If less than 5 ohms

- Test for less than 5 ohms between the control circuit terminal 2 and ground.

- If 5 ohms or greater

- Ignition Off, disconnect the harness connector at the K20 Engine Control Module.

- Test for less than 2 ohms in the control circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K20 Engine Control Module.

- If less than 5 ohms

- Ignition On.

NOTE: A test lamp must be used for this test. The control circuit is pulled-up to a low current voltage, 1.5-3.5 V on the control circuit is normal.

- Verify that a test lamp does not illuminate between the control circuit terminal 2 and ground.

- If the test lamp illuminates

- Ignition Off, disconnect the harness connector at the K20 Engine Control Module, ignition On.

- Test for less than 1 V between the control circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit

- If less than 1 V, replace the K20 Engine Control Module

- If the test lamp does not illuminate

- Remove the test lamp.

- Connect the DMM black lead to the control circuit terminal 2. Connect the DMM red lead to B+. Set the DMM on the diode setting. Command the CMP actuator solenoid On and Off with a scan tool. The DMM should transition from OL when commanded Off to less than 1 V when commanded On.

- If the circuit voltage does not correspond to the specified values

- Ignition Off, disconnect the harness connector at the K20 Engine Control Module.

- Test for less than 2 ohms in the control circuit end to end.

- If 2 ohms or greater, repair the open/high resistance or short to ground in the circuit

- If less than 2 ohms, replace the K20 Engine Control Module

- If the circuit voltage corresponds to the specified values

- Test or replace the appropriate camshaft position actuator solenoid valve.

Component Testing

- Ignition Off, disconnect the harness connector at the appropriate Q6 Camshaft Position Actuator Solenoid Valve.

- Test for 7-12 ohms between the control terminal 2 and the low reference circuit terminal 1.

- If not between 7-12 ohms

Replace the Q6 Camshaft Position Actuator Solenoid Valve.

- If between 7-12 ohms

- Test for infinite resistance between each terminal and the Q6 Camshaft Position Actuator Solenoid Valve housing

- If less than infinite resistance

Replace the Q6 Camshaft Position Actuator Solenoid Valve.

- If infinite resistance

- All OK.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Camshaft Position Actuator Solenoid Valve Replacement

- Control Module References for Engine Control Module replacement, programming and setup.

DTC P0011 OR P0014

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptors

DTC P0011

Intake Camshaft Position System Performance

DTC P0014

Exhaust Camshaft Position System Performance

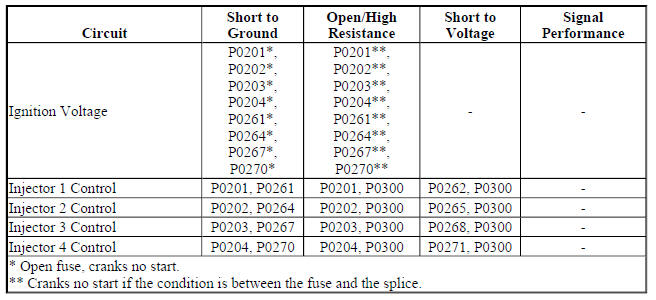

Diagnostic Fault Information

.jpg)

Circuit/System Description

The camshaft position (CMP) actuator system enables the engine control module (ECM) to change the timing of the camshafts while the engine is operating. The camshaft position actuator solenoid valves are operated hydraulically in order to change the angle of the camshaft relative to crankshaft position. The camshaft position actuator solenoid valves are controlled by the engine control module (ECM). The ECM sends a pulse width modulated signal to the camshaft position actuator solenoid valves. The camshaft position actuator solenoid valves control the amount of engine oil flow that applies the pressure to advance or retard the camshafts.

Conditions for Running the DTC

- DTC P0010, P0013, P0016, P0017, P0335, P0340, P0341, P0365, or P0366 is not set.

- The engine is running.

- The ignition voltage is between 11-32 V.

- The camshaft position actuator is enabled.

- The rate of change in the camshaft position is less than 3º for 4 s.

- DTCs P0011 and P0014 runs continuously once the above conditions are met for greater than 0.1 s.

Conditions for Setting the DTC

The ECM detects a difference between the camshaft position angle and the desired camshaft position angle is greater than 6 to 10º based on engine coolant temperature and engine speed.

Action Taken When the DTC Sets

DTCs P0011 and P0014 are Type B DTCs.

Conditions for Clearing the DTC

DTCs P0011 and P0014 are Type B DTCs.

Diagnostic Aids

- The engine oil condition has a major impact on the camshaft actuator system.

- A low oil level condition may set this DTC. The engine may require an oil change. Inquire with the customer when the last oil change was performed. You may also monitor the scan tool Engine Oil Life Remaining parameter. Advise the customer an oil change may be required.

- Inspect the engine for any recent engine mechanical repairs. An incorrectly installed camshaft, camshaft actuator, or timing belt can cause this DTC to set.

- A resistance greater than 8 ohms on the camshaft position actuator solenoid valve control circuit may set this DTC. If you suspect high resistance, ground the control circuit while the engine is idling. The scan tool Intake or Exhaust Camshaft Position Actuator Solenoid Valve Control Circuit Low Voltage Test Status should display Malfunction. If the parameter displays OK, test the control circuit for high resistance.

Reference Information

Schematic Reference

ENGINE CONTROLS SCHEMATICS (Encore) ENGINE CONTROLS SCHEMATICS (Encore)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Component View Reference

Powertrain Component Views

Description and Operation

Camshaft Actuator System Description

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

DTC Type Reference

Powertrain Diagnostic Trouble Code (DTC) Type Definitions (LUV) , Powertrain Diagnostic Trouble Code (DTC) Type Definitions (2H0)

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Verification

NOTE:

- The engine oil level and the oil pressure are critical to the correct operation of the camshaft position actuator system. Verify that the engine has the correct oil level and the correct oil pressure before continuing with this diagnostic.

- The engine oil condition has a major impact on the camshaft actuator

system. Debris in the oil can interfere with the camshaft position

actuator solenoid and the mechanical camshaft actuator operation.

Inspect for dirty or degraded crankcase oil. The engine may require an oil change. Inquire with the customer when the last oil change was performed. You may also monitor the scan tool Engine Oil Life Remaining parameter. Advise the customer an oil change may be required.

- Ignition On.

- Verify the correct engine oil level and pressure. Refer to OIL PRESSURE DIAGNOSIS AND TESTING

- If the oil level and the oil pressure are not correct

Repair as necessary

- If the oil level and the oil pressure are correct

NOTE: If a crankshaft or camshaft position sensor DTC is set, the scan tool Camshaft Position Actuator output control will not function.

- Verify DTC P0010, P0013, P0016, P0017, P0335, P0336, P0340, P0341, P0365, P0366, P2088, P2089, P2090 or P2091 is not set.

- If any of the DTCs are set

Refer to Diagnostic Trouble Code (DTC) List - Vehicle for further diagnosis.

- If none of the DTCs are set

- Engine idling.

- Verify the scan tool parameters are less than 2º in each of the commanded states when commanding the Camshaft Position Actuator from 0-20º and back to 0º with the scan tool.

- Intake Camshaft Position Variance

- Exhaust Camshaft Position Variance

- Intake Camshaft Position Variance

- Exhaust Camshaft Position Variance

- If 2º or greater

Refer to Circuit/System Testing.

- If less than 2º

- Verify that DTC P0011 or P0014 is not set.

- If any of the DTCs are set

Refer to Circuit/System Testing.

- If none of the DTCs set

- Operate the vehicle within the Conditions for Running the DTC. You may also operate the vehicle within the conditions that you observed from the Freeze Frame/Failure Records data.

- Verify the DTC does not set.

- If the DTC sets

Refer to Circuit/System Testing.

- If the DTC does not set

- All OK.

Circuit/System Testing

- Ignition Off, disconnect the harness connector at the appropriate Q6 Camshaft Position Actuator Solenoid Valve. It may take up to 2 minutes for all vehicle systems to power down.

- Test for less than 5 ohms between the low reference circuit terminal 1 and ground.

- If 5 ohms or greater

- Ignition Off, disconnect the harness connector at the K20 Engine Control Module.

- Test for less than 2 ohms in the low reference circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K20 Engine Control Module.

- If less than 5 ohms

- Ignition On.

NOTE: A test lamp must be used for this test. The control circuit is pulled-up to a low current voltage, 1.5-4.5 V on the control circuit is normal.

- Verify that a test lamp does not illuminate between the control circuit terminal 2 and ground.

- If the test lamp illuminates

- Ignition Off, disconnect the harness connector at the K20 Engine Control Module, ignition On.

- Test for less than 1 V between the control circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V, replace the K20 Engine Control Module.

- If the test lamp does not illuminate

- Remove the test lamp.

- Verify the scan tool parameters listed below do not display Malfunction when commanding the appropriate Camshaft Position Actuator Solenoid Valve On with a scan tool.

- Intake Camshaft Position Actuator Solenoid Valve Control Circuit Low Voltage Test Status

- Exhaust Camshaft Position Actuator Solenoid Valve Control Circuit Low Voltage Test Status

- Intake Camshaft Position Actuator Solenoid Valve Control Circuit Low Voltage Test Status

- Exhaust Camshaft Position Actuator Solenoid Valve Control Circuit Low Voltage Test Status

- If Malfunction is displayed

- Ignition Off, disconnect the harness connector at the K20 Engine Control Module.

- Test for less than 2 ohms in the control circuit end to end.

- If 2 ohms or greater, repair the open/high resistance or short to ground in the circuit.

- If less than 2 ohms, replace the K20 Engine Control Module.

- If Malfunction is not displayed

- Ignition Off, remove the Q6 Camshaft Position Actuator Solenoid Valve.

- Verify the conditions listed below do not exist with the Q6 Camshaft Position Actuator Solenoid Valve:

- Torn, restricted, mis-positioned, or missing screens.

- Engine oil leak between the oil sealing lands of the solenoid. Inspect the lands of the solenoid for nicks.

- Oil seepage at the solenoid connector.

- If a condition is found

Replace the Q6 Camshaft Position Actuator Solenoid Valve.

- If a condition is not found

NOTE: After swapping toe solenoids, install jumper wires to the appropriate terminals of the harness connectors and the solenoids.

- Ignition Off, swap the Q6 Camshaft Position Actuator Solenoid Valve with the Q6 Camshaft Position Actuator Solenoid Valve that is operating correctly.

- Engine idling.

- Verify the scan tool Camshaft Position Variance parameter is less than 2º in each of the commanded states when commanding the Camshaft Position Actuator from 0-20º and back to 0º with a scan tool.

- If 2º or greater

Replace the mechanical camshaft position actuator.

- If less than 2º

- Test or replace the Q6 Camshaft Position Actuator Solenoid Valve.

Component Testing

- Ignition Off, disconnect the harness connector at the appropriate Q6 Camshaft Position Actuator Solenoid Valve.

- Test for 7-12 ohms between the control terminal 2 and the low reference circuit terminal 1.

- If not between 7-12 ohms

Replace the Q6 Camshaft Position Actuator Solenoid Valve.

- If between 7-12 ohms

- Test for infinite resistance between each terminal and the Q6 Camshaft Position Actuator Solenoid Valve housing.

- If less than infinite resistance

Replace the Q6 Camshaft Position Actuator Solenoid Valve.

- If infinite resistance

- All OK

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Camshaft Position Actuator Solenoid Valve Replacement

- Control Module References for ECM replacement, programming and setup

DTC P0016 OR P0017

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptors

DTC P0016

Crankshaft Position - Intake Camshaft Position Not Plausible

DTC P0017

Crankshaft Position - Exhaust Camshaft Position Not Plausible

Circuit/System Description

The engine control module (ECM) uses the crankshaft position sensor, intake camshaft position sensor, and the exhaust camshaft position sensor information to monitor the correlation between the crankshaft, intake camshaft, and exhaust camshaft position.

Conditions for Running the DTC

- DTCs P0335, P0336, P0340, P0341, P0365, P0366, P0641, or P0651 is not set

- The engine is running.

- The camshaft position actuator solenoid valves are in the parked position.

The DTCs run continuously once the above conditions are met.

Conditions for Setting the DTC

The ECM detects a camshaft to crankshaft misalignment. The DTC sets if the crankshaft position sensor signal is 10 degrees before or after the normal position in relation to the crankshaft angle while the engine is running.

Action Taken When the DTC Sets

DTCs P0016 and P0017 are Type B DTCs.

Conditions for Clearing the DTC

DTCs P0016 and P0017 are Type B DTCs.

Diagnostic Aids

The following conditions can also set the DTCs:

- A short to ground in a camshaft position actuator solenoid valve control circuit.

- Crankshaft end play out of specification.

- A crankshaft reluctor wheel that has moved in relationship to top dead center (TDC).

Reference Information

Description and Operation

Camshaft Actuator System Description

DTC Type Reference

Powertrain Diagnostic Trouble Code (DTC) Type Definitions (LUV) , Powertrain Diagnostic Trouble Code (DTC) Type Definitions (2H0)

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Verification

- Ignition ON.

- Verify DTC P0335, P0336, P0340, P0341, P0365, P0366, P0641 or P0651 is not set.

- If any of the DTCs are set

Refer to Diagnostic Trouble Code (DTC) List - Vehicle .

- If none of the DTCs are set

- Engine Running at normal operating temperature.

- Verify DTC P0016 or P0017 is not set.

- If the DTC is set

Inspect for the following and repair as necessary:

- A Q6 Camshaft Position Actuator Solenoid Valve that is stuck in the full advance or retard position.

- The correct installation of the Q6 Camshaft Position Actuator Solenoid Valves.

- The correct installation of the B23 Camshaft Position Sensors.

- The correct installation of the B26 Crankshaft Position Sensor.

- A timing chain tensioner condition.

- An incorrectly installed timing chain.

- Excessive play in the timing chain.

- A crankshaft reluctor wheel that has moved in relationship to top dead center (TDC) on the crankshaft.

- If the DTC is not set

- Operate the vehicle within the Conditions for Running the DTC. You may also operate the vehicle within the conditions that you observed from the Freeze Frame/Failure Records data.

- Verify the DTC does not set.

- If the DTC sets

A mechanical condition listed above still exists.

- If the DTC does not set

- All OK.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Camshaft Position Actuator Solenoid Valve Replacement

- Camshaft Position Sensor Replacement

- Crankshaft Position Sensor Replacement

- Timing Chain Tensioner Replacement

DTC P0030-P0032, P0036-P0038, P0053, P0054, P0135, OR P0141

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provide an overview of each diagnostic category.

DTC Descriptors

DTC P0030

HO2S Heater Control Circuit Sensor 1

DTC P0031

HO2S Heater Control Circuit Low Voltage Sensor 1

DTC P0032

HO2S Heater Control Circuit High Voltage Sensor 1

DTC P0036

HO2S Heater Control Circuit Sensor 2

DTC P0037

HO2S Heater Control Circuit Low Voltage Sensor 2

DTC P0038

HO2S Heater Control Circuit High Voltage Sensor 2

DTC P0053

HO2S Heater Resistance Sensor 1

DTC P0054

HO2S Heater Resistance Sensor 2

DTC P0135

HO2S Heater Performance Sensor 1

DTC P0141

HO2S Heater Performance Sensor 2

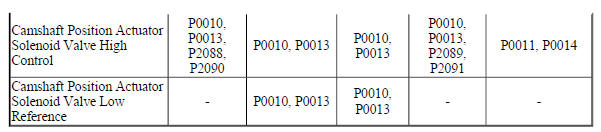

Diagnostic Fault Information

.jpg)

Typical Scan Tool Data

HO2S Sensor 1 Current/HO2S Sensor 2 Current

.jpg)

Circuit/System Description

Heated oxygen sensors (HO2S) are used for fuel control and post-catalyst monitoring. Each HO2S compares the oxygen content of the surrounding air with the oxygen content in the exhaust stream. Each HO2S must reach operating temperature to provide an accurate voltage signal. A heating element inside each of the HO2S minimizes the time required for the sensor to reach operating temperature. Voltage is provided to the heater by an ignition voltage circuit through a fuse. With the engine running, ground is provided to the heater by the HO2S heater low control circuit, through a low side driver within the engine control module (ECM). The ECM uses pulse-width modulation (PWM) to control the HO2S heater operation to maintain a specific HO2S operating temperature range.

Conditions for Running the DTC

P0030, P0031, P0032, P0036, P0037 and P0038

- The system voltage is between 11-32 V.

- The engine speed is greater than 400 RPM.

- The DTCs run continuously when the above conditions are met for greater than 5 s.

P0053 and P0054

- DTCs P0111, P0112, P0113, P0114, P0116, P0117, P0118, P0119 or P2610 are not set.

- The system voltage is less than 32 V.

- The ignition is OFF for greater than 8 h.

- The engine is running.

- The ECT is between -30 to +45ºC (-22 to +113ºF).

- The engine coolant temperature (ECT) and the intake air temperature (IAT) are within 8ºC (14ºF).

- The DTCs run once per valid cold start-up when the above conditions are met

P0135 and P0141

- DTCs P0116, P0117, P0118, P0119 or P0128 are not set.

- The system voltage is between 10-32 V.

- The HO2S heaters are at operating temperature.

- The scan tool HO2S Heater device control is not active.

- The commanded HO2S heater duty cycle is greater than 0%.

- The DTCs run twice per drive cycle when the above conditions are met for greater than 30 s.

Conditions for Setting the DTC

P0030, P0031, P0032, P0036, P0037 and P0038

The ECM detects that the commanded state of the driver and the actual state of the control circuit do not match for greater than 5 s.

P0053 and P0054

The ECM detects the HO2S heater is not within 7.5-13 ohms at engine start-up.

P0135 and P0141

The ECM detects the HO2S heater current is less than 0.30 A or greater than 2.5 A for greater than 8 s.

Action Taken When the DTC Sets

DTC P0030, P0031, P0032, P0036, P0037, P0038, P0053, P0054, P0135, and P0141 are Type B DTCs.

Conditions for Clearing the DTC

DTC P0030, P0031, P0032, P0036, P0037, P0038, P0053, P0054, P0135, and P0141 are Type B DTCs.

Diagnostic Aids

- If the condition is intermittent, move the related harnesses and connectors, with the engine operating, while monitoring the scan tool circuit status parameters for the component. The circuit status parameters will change from OK or Not Run to Malfunction if there is a condition with the circuit or a connection.

- An open fuse in the HO2S heater circuit may be caused by the heater element in one of the sensors. The condition may not be present until the sensor operates for a period of time. If no fault is present in the heater circuit, monitor the amperage of each heater with a scan tool to determine if one of the heater elements is the cause of the open fuse. Inspect the sensor pigtail or the harness for contacting the exhaust system.

Reference Information

Schematic Reference

Engine Controls Schematics (Encore) , Engine Controls Schematics (Encore)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

DTC Type Reference

Powertrain Diagnostic Trouble Code (DTC) Type Definitions (LUV) , Powertrain Diagnostic Trouble Code (DTC) Type Definitions (2H0)

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Verification

- Engine idling.

- Verify the parameters listed below do not display Malfunction.

- HO2S 1 or 2 Heater Control Circuit Low Voltage Test Status

- HO2S 1 or 2 Heater Control Circuit Open Test Status

- HO2S 1 or 2 Heater Control Circuit High Voltage Test Status

- If Malfunction is displayed

Refer to Circuit/System Testing.

- If Malfunction is not displayed

- Operate the vehicle within the conditions for running the DTC. You may also operate the vehicle within the conditions that you observed from the Freeze Frame/Failure Records data.

- Verify the DTC does not set.

- If the DTC sets

Refer to Circuit/System Testing.

- If the DTC does not set

- All OK.

Circuit/System Testing

- Ignition OFF, disconnect the harness connector at the appropriate B52 Heated Oxygen Sensor. Ignition ON.

- Verify that a test lamp illuminates between the ignition voltage circuit terminal 1 and ground.

- If the test lamp does not illuminate and the circuit fuse is good

- Ignition OFF.

- Test for less than 2 ohms in the ignition circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, verify the fuse is OK and there is voltage at the fuse.

If the test lamp does not illuminate and the circuit fuse is open

- Ignition OFF, remove the test lamp.

- Test for infinite resistance between the ignition circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance, test all components connected to the fuse and replace as necessary.

- If the test lamp illuminates

- Verify that a test lamp does not illuminate between the ignition voltage circuit terminal 1 and the control circuit terminal 2.

- If the test lamp illuminates

- Ignition OFF, remove the test lamp, disconnect the harness connector at the K20 Engine Control Module.

- Test for infinite resistance between the control circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance, replace the K20 Engine Control Module.

- If the test lamp does not illuminate

- Remove the test lamp.

- Verify the scan tool HO2S 1 or 2 Heater Control Circuit High Voltage Test Status parameter is OK when commanding the HO2S Heater Sensor 1 or 2 ON with a scan tool.

- If OK is not displayed

- Ignition OFF, disconnect the harness connector at the K20 Engine Control Module, ignition ON.

- Test for less than 1 V between the control circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V, replace the K20 Engine Control Module.

- If OK is displayed

NOTE:

- Less than 10 ohms of additional resistance on the ignition voltage circuit, or control circuit may set a DTC. If there is a resistance on a circuit, the driver will remain ON and the scan tool HO2S High Voltage Test Status parameter will display OK.

- Performing this test may set additional DTCs.

- Install a 10 A fused jumper wire between the control circuit terminal 2 and the ignition voltage circuit terminal 1.

NOTE: This test may only be performed once per key cycle. If test is repeated, ignition OFF, allow the engine control module to shut down completely, then ignition ON.

- Verify the scan tool HO2S 1 or 2 Heater Control Circuit High Voltage Test Status parameter is Malfunction when commanding the HO2S Heater Sensor 1 or 2 ON with a scan tool.

- If Malfunction is not displayed

- Ignition OFF, remove the jumper wire, disconnect the harness connector at the K20 Engine Control Module.

- Test for less than 2 ohms in the control circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K20 Engine Control Module.

- If Malfunction is displayed

- Test or replace the B52 Heated Oxygen Sensor.

Component Testing

- Ignition OFF, disconnect the harness connector at the appropriate B52 Heated Oxygen Sensor.

- Test for 8-20 ohms between the ignition voltage circuit terminal 1 and the control circuit terminal 2.

- If not within the specified range

Replace the B52 Heated Oxygen Sensor.

- If within the specified range

- All OK.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Heated Oxygen Sensor Replacement - Sensor 1

- Heated Oxygen Sensor Replacement - Sensor 2

- Perform the scan tool Heated Oxygen Sensor Resistance Learn Reset after replacing a HO2S.

- Control Module References for ECM replacement, programming and setup.

DTC P0033-P0035

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptors

DTC P0033

Turbocharger Bypass Solenoid Valve Control Circuit

DTC P0034

Turbocharger Bypass Solenoid Valve Control Circuit Low Voltage

DTC P0035

Turbocharger Bypass Solenoid Valve Control Circuit High Voltage

Diagnostic Fault Information

.jpg)

.jpg)

Circuit/System Description

The turbocharger incorporates a wastegate that is controlled by a pressure differential, that is determined by the engine control module (ECM) by means of a PWM solenoid valve, in order to regulate the pressure ratio of the turbocharger. A turbocharger bypass valve also controlled by the ECM by utilizing a remotely mounted solenoid valve is integrated into the bypass valve to prevent turbocharger surging and damage from vibrations by opening during abrupt closed throttle conditions. When the valve is open during closed throttle deceleration conditions, the bypass valve allows the air to recirculate in the turbocharger and maintain turbocharger speed.

Within a calibrated range during the closed throttle event, or upon a wide open throttle command the valve will then close to optimize turbo response. The bypass solenoid valve has the following circuits:

- Ignition voltage

- Turbocharger bypass solenoid valve control

As engine load and engine speed increases, the turbocharger bypass solenoid valve remains commanded ON by the ECM. As soon as the throttle closes the turbocharger bypass solenoid valve is commanded OFF by the ECM, in order to allow the turbocharger bypass valve to open and allow the turbocharger air to recirculate, there by preventing turbocharger surging.

Conditions for Running the DTC

- The engine is not cranking.

- The powertrain relay voltage is greater than 11 V.

- The run/crank voltage is greater than 6 V.

- The DTC run continuously when the above conditions are met.

Conditions for Setting the DTC

The ECM detects an open, a short to ground, or a short to voltage on the turbocharger bypass solenoid valve control circuit for greater than 1 s.

Action Taken When the DTC Sets

DTC P0033, P0034, P0035 are Type B DTCs.

Conditions for Clearing the DTC

DTC P0033, P0034, P0035 are Type B DTCs

Reference Information

Schematic Reference

Engine Controls Schematics (Encore) , Engine Controls Schematics (Encore)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Description and Operation

Turbocharger System Description

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

DTC Type Reference

Powertrain Diagnostic Trouble Code (DTC) Type Definitions (LUV) , Powertrain Diagnostic Trouble Code (DTC) Type Definitions (2H0)

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Verification

- Ignition ON, Verify the parameters listed below do not display Malfunction when commanding the Turbocharger Bypass Solenoid Valve ON and OFF with a scan tool:

- Turbocharger Bypass Solenoid Valve Control Circuit Low Voltage Test Status

- Turbocharger Bypass Solenoid Valve Control Circuit Open Test Status

- Turbocharger Bypass Solenoid Valve Control Circuit High Voltage Test Status

- If Malfunction is displayed

Refer to Circuit/System Testing.

- If Malfunction is not displayed

- Operate the vehicle within the Conditions for Running the DTC. You may also operate the vehicle within the conditions that you observed from the Freeze Frame/Failure Records data.

- Verify a DTC does not set.

- If a DTC sets

Refer to Circuit/System Testing

- If a DTC does not set

- All OK

Circuit/System Testing

- Ignition OFF, disconnect the harness connector at the Q40 Turbocharger Bypass Solenoid Valve. Ignition ON.

- Verify a test lamp illuminates between the ignition circuit terminal 2 and ground.

- If the test lamp does not illuminate and the circuit fuse is good

- Ignition OFF, remove the test lamp.

- Test for less than 2 ohms in the ignition circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, verify the fuse is not open and there is voltage at the fuse.

- If the test lamp does not illuminate and the circuit fuse is open

- Ignition OFF, remove the test lamp.

NOTE: An internal short in any component supplied by the fuse may cause the fuse to open and set a DTC when the component is activated.

- Test for infinite resistance between the ignition circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance, test all components connected to the ignition voltage circuit for a short and replace as necessary.

If the test lamp illuminates

- Verify that a test lamp does not illuminate between the control circuit terminal 1 and the ignition circuit terminal 2.

- If the test lamp illuminates

- Ignition OFF, disconnect the harness connector at the K20 Engine Control Module. Remove the test lamp.

- Test for infinite resistance between the control circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance, replace the K20 Engine Control Module.

If the test lamp does not illuminate

- Remove the test lamp.

- Verify the scan tool Turbocharger Bypass Solenoid Valve Control Circuit High Voltage Test Status parameter is OK when commanding the Turbocharger Bypass Solenoid Valve Active with a scan tool.

- If OK is not displayed

- Ignition OFF, disconnect the harness connector at the K20 Engine Control Module, ignition ON.

- Test for less than 1 V between the control circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V, replace the K20 Engine Control Module.

If OK is displayed

- Install a 3 A fused jumper wire between the control circuit terminal 1 and the ignition circuit terminal 2.

- Verify the scan tool Turbocharger Bypass Solenoid Valve Control Circuit High Voltage Test Status parameter is Malfunction when commanding the Turbocharger Bypass Solenoid Valve Active with a scan tool.

If Malfunction is not displayed

- Ignition OFF, disconnect the harness connector at the K20 Engine Control Module.

- Test for less than 2 ohms in the control circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K20 Engine Control Module.

If Malfunction is displayed

- Test or replace the Q40 Turbocharger Bypass Solenoid Valve.

Component Testing

Static Test

- Ignition OFF, disconnect the harness connector at the Q40 Turbocharger Bypass Solenoid Valve.

- Test for 20-27 ohms between terminal 1 and terminal 2 of the solenoid valve

If not between 20-27 ohms

Replace the Q40 Turbocharger Bypass Solenoid Valve.

If between 20-27 ohms

- All OK

Dynamic Test

- Install a 10 A fused jumper wire between the Ignition terminal 2 and 12 V. Install a jumper wire between the control terminal 1 and ground.

- Verify the solenoid clicks.

If the solenoid does not click

Replace the Q40 Turbocharger Bypass Solenoid Valve.

If the solenoid clicks

- All OK

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Charge Air Bypass Regulator Solenoid Valve Replacement

- Control Module References for ECM replacement, programming and setup

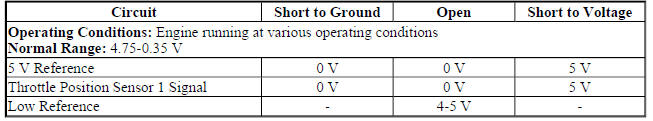

DTC P0068 OR P1101

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptor

DTC P0068

Throttle Body Air Flow Performance

DTC P1101

Intake Air Flow System Performance

Circuit/System Description

The engine control module (ECM) compares actual airflow based on throttle position (TP) to a calculated airflow based on manifold absolute pressure (MAP) sensor, and mass air flow (MAF).

Conditions for Running the DTC

DTC P0068

- The engine speed is at least 800 RPM.

- The ignition voltage is at least 6.4 V.

- The DTC runs continuously when the above conditions are met.

DTC P1101

- DTC P0102, P0103, P0107, P0111, P0112, P0113, P0116, P0117, P0118, P0335,or P0336 is not set

- The engine speed is between 400-7,000 RPM

- The engine coolant temperature (ECT) is between -7 to +125ºC (+19 to +257ºF).

- The intake air temperature (IAT) is between -20 to +125ºC (-4 to +257ºF).

- The DTC runs continuously when the above conditions are met.

Conditions for Setting the DTCs

The ECM detects that the actual airflow rate is greater than the calculated airflow.

Action Taken When the DTCs Set

- DTC P0068 is a type A DTC.

- DTC P0068 is a type B DTC; with RPO LDD.

- DTC P1101 is a type B DTC.

Conditions for Clearing the DTCs

- DTC P0068 is a type A DTC.

- DTC P0068 is a type B DTC; with RPO LDD.

- DTC P1101 is a type B DTC.

Reference Information

Schematic Reference

Engine Controls Schematics (Encore) , Engine Controls Schematics (Encore)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

Powertrain Component Views

Powertrain Component Views

DTC Type Reference

Powertrain Diagnostic Trouble Code (DTC) Type Definitions (LUV) , Powertrain Diagnostic Trouble Code (DTC) Type Definitions (2H0)

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Verification

- Ignition ON.

- Verify that DTC DTC P0641, P0651, P0697, or P06A3 is not set.

- If any of the DTCs are set

Refer to DTC P0641, P0651, P0697, or P06A3 (ECM) for further diagnosis.

- If none of the DTCs are set

- Ignition ON.

- Verify the scan tool Throttle Body Idle Airflow Compensation parameter is less than 90 %.

- If 90 % or greater

Refer to Throttle Body Inspection and Cleaning .

- If less than 90 %

- Verify the scan tool Throttle Position Sensors 1 and 2 Agree/Disagree parameter displays Agree while performing the Throttle Sweep Test with a scan tool.

- If Disagree

Refer to DTC P0121-P0123, P0222, P0223, or P2135 for further diagnosis.

- If Agree

- Determine the current vehicle testing altitude.

- Verify the scan tool MAP Sensor pressure parameter is within the range specified in the Altitude Versus Barometric Pressure table.

- If the MAP Sensor parameter is not in range

Refer to DTC P0106 for further diagnosis.

- If the MAP Sensor parameter is within range

- Verify the engine is equipped with a turbocharger.

- If not equipped with a turbocharger

Refer to Step 11.

- If equipped with a turbocharger

- Verify the scan tool Boost Pressure Sensor parameter is within the range specified in the Altitude Versus Barometric Pressure table.

- If the Boost Pressure Sensor parameter is not in range

Refer to DTC P0236 for further diagnosis.

- If the Boost Pressure Sensor parameter is within range

- Verify the scan tool Boost Pressure Sensor parameter decreases after starting the engine.

- If the Boost Pressure Sensor parameter does not decrease

Refer to DTC P0236 for further diagnosis.

- If the Boost Pressure Sensor parameter is within range

- Engine idling, verify the scan tool MAP Sensor pressure parameter is between 26-52 kPa (3.8-7.5 PSI) and changes with accelerator pedal input.

- If not between 26-52 kPa (3.8-7.5 PSI) or does not change

Refer to DTC P0106 for further diagnosis.

- If between 26-52 kPa (3.8-7.5 PSI) and changes

- Verify the scan tool MAF Sensor g/s parameter changes smoothly and gradually as the engine speed is increased and decreased while performing the actions listed below.

- Engine idling

- Perform the scan tool snapshot function.

- Increase the engine speed slowly to 3,000 RPM and then back to idle.

- Exit from the scan tool snapshot and review the data.

- Observe the MAF Sensor parameter frame by frame with a scan tool.

- If the MAF Sensor parameter does not change smoothly and gradually

Refer to DTC P0101 for further diagnosis.

- If the MAF Sensor parameter changes smoothly and gradually

- Operate the vehicle within the Conditions for Running the DTC. You may also operate the vehicle within the conditions that you observed from the Freeze Frame/Failure Records data.

- Verify the DTC does not set.

- If the DTC does set

Refer to Circuit/System Testing for further diagnosis.

- If the DTC does not set

- All OK

Circuit/System Testing

NOTE: You must perform the Circuit/System Verification before proceeding with Circuit/System Testing.

- Verify the integrity of the entire air induction system by verifying that none of the following conditions exist:

- Any damaged components

- Improper operation of turbocharger wastegate actuator or bypass valve; where equipped

- Improperly installed components

- Collapsed, restricted, or damaged components

- Loose clamps, cracks, or other damage

- An air flow restriction

- Restricted air filter

- Splits, kinks, leaks, or improper connections at the vacuum hoses

- Vacuum leaks at the intake manifold, MAP sensor, and throttle body

- Water intrusion

- Any snow or ice buildup, in cold climates

- Contamination of the MAF sensor element

- Missing, restricted, or leaking exhaust components-Refer to Symptoms - Engine Exhaust for further diagnosis.

- If a condition is found

Repair or replace component as appropriate.

- If no condition is found

- Test the engine for a mechanical condition. Refer to Symptoms - Engine Mechanical for diagnosis.

- If a condition is found

Repair or replace component as appropriate.

- If no condition is found

- All OK

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

Control Module References for engine control module replacement, programming, and setup

DTC P0096 OR P0111

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptors

DTC P0096

Intake Air Temperature (IAT) Sensor 2 Performance

DTC P0111

Intake Air Temperature (IAT) Sensor 1 Performance

Diagnostic Fault Information

IAT Sensor 1

.jpg)

IAT Sensor 2

.jpg)

Typical Scan Tool Data

IAT Sensor 1

.jpg)

IAT Sensor 2

.jpg)

Circuit/System Description

The sensors listed below are integrated within the multifunction intake air sensor:

- IAT sensor 1

- IAT sensor 2

- Humidity sensor

- MAF sensor

- BARO pressure sensor

The intake air temperature (IAT) sensor 1 is a variable resistor that changes the voltage on the engine control module (ECM) supplied 5 V signal circuit. The signal varies with inlet air temperature in the sensor bore and is displayed by the scan tool as ºC (ºF). The IAT sensor 2 and the humidity sensor share the same circuit. The IAT sensor 2 signal is displayed by the scan tool as Hz (Hertz) and ºC (ºF).

The IAT sensor 1 produces an analog signal on pin-8 of the sensor. The IAT sensor 2 produces a frequency modulated signal on pin-1 of the sensor.

The sensors listed below share an ECM supplied 5 V reference circuit:

- IAT sensor 2

- Humidity sensor

- Barometric pressure (BARO) sensor

The sensors listed below share an ECM supplied low reference circuit:

- IAT sensor 1

- IAT sensor 2

- Humidity sensor

- Barometric pressure (BARO) sensor

IAT Sensor 1 - Temperature, Resistance, Voltage Table

.jpg)

IAT Sensor 2 - Temperature, Frequency Table

.jpg)

Conditions for Running the DTCs

P0096 and P0111

- DTCs P0097, P0098, P0111, P0112, P0113, P0117, P0118, P00EA, P00EB, or P1682 are not set.

- The ignition has been OFF at least 8 hours.

- Ignition voltage is at least 11 V.

- These DTCs run once per ignition cycle when the enabling conditions are met.

Conditions for Setting the DTCs

P0096

- The ECM determines the absolute difference between IAT sensor 1 start-up temperature and the IAT sensor 2 start-up temperature is greater than 25ºC (45ºF).

AND

- The ECM determines the absolute difference between IAT sensor 2 start-up temperature and the IAT sensor 3 start-up temperature is greater than 25ºC (45ºF).

AND

- The ECM determines the absolute difference between IAT sensor 1 start-up temperature and the IAT sensor 3 start-up temperature is less than or equal to 25ºC (45ºF).

- This DTC runs once per ignition cycle when the enabling conditions are met.

NOTE: P0111 Can fail under any of the following 3 sets of conditions.

P0111 - Condition 1

- The ECM determines the absolute difference between IAT sensor 1 start-up temperature and the IAT sensor 2 start-up temperature is greater than 25ºC (45ºF).

AND

- The ECM determines the absolute difference between IAT sensor 1 start-up temperature and the IAT sensor 3 start-up temperature is greater than 25ºC (45ºF).

AND

- The ECM determines the absolute difference between IAT sensor 2 start-up temperature and the IAT sensor 3 start-up temperature is less than or equal to 25ºC (45ºF).

P0111 - Condition 2

- The ECM determines the IAT sensor 2 start-up temperature is between the IAT sensor 1 and IAT sensor 3 start-up temperatures.

AND

- The ECM determines the absolute difference between IAT sensor 1 start-up temperature and the IAT sensor 3 start-up temperature is greater than 25ºC (45ºF).

AND

- The ECM determines the absolute difference between IAT sensor 2 and the IAT sensor 1 start-up temperatures is greater than absolute difference between IAT sensor 2 and the IAT sensor 3 start-up temperatures.

P0111 - Condition 3

- The ECM determines the IAT sensor 3 start-up temperature is between the IAT sensor 1 and IAT sensor 2 start-up temperatures

AND

- The ECM determines the absolute difference between IAT sensor 1 start-up temperature and the IAT sensor 2 start-up temperature is greater than 25ºC (45ºF).

AND

- The ECM determines the absolute difference between IAT sensor 3 and the IAT sensor 1 start-up temperatures is greater than absolute difference between IAT sensor 3 and the IAT sensor 2 start-up temperatures.

DTC P0111 runs once an ignition cycle when the any one, of the above 3 enabling sets of conditions is met.

Action Taken When the DTCs Set

DTCs P0096 and P0111 are Type B DTCs.

Conditions for Clearing the DTCs

DTCs P0096 and P0111 are Type B DTCs.

Diagnostic Aids

- With the ignition ON, when the engine is OFF and is cold; properly functioning IAT sensors 1 and 2 will gradually increase the scan tool IAT Sensor 1 and 2 parameters. This is due to the heat that is generated by the multifunction intake air sensor internal heating elements.

- The Humidity sensor and the IAT sensor 2 signals are sent to the ECM on the same circuit. If the IAT Sensor 2 parameter displays the values: 10 Hz; -40ºC (-40ºF), and there are also Humidity Sensor DTCs, check for a circuit problem.

Reference Information

Schematic Reference

Engine Controls Schematics (Encore) , Engine Controls Schematics (Encore)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

DTC Type Reference

Powertrain Diagnostic Trouble Code (DTC) Type Definitions (LUV) , Powertrain Diagnostic Trouble Code (DTC) Type Definitions (2H0)

Scan Tool Reference

Control Module References for scan tool information

Special Tools

EL-38522-A Variable Signal Generator

For equivalent regional tools, refer to Special Tools (Diagnostic Tools)

Circuit/System Verification

- Ignition ON.

- Verify that DTC DTC P0641, P0651, P0697, or P06A3 is not set.

- If any of the DTCs are set

Refer to DTC P0641, P0651, P0697, or P06A3 (ECM) for further diagnosis.

- If none of the DTCs are set

NOTE: To minimize the effects of residual engine heat and sensor internal heating elements, perform Steps 3 and 4 of this verification procedure only if the ignition has been OFF for 8 hours or more.

- Ignition ON.

- Verify the following scan tool parameters are within 25ºC (45ºF) of each other.

- Start-Up IAT Sensor 1

- IAT Sensor 2

- IAT Sensor 3; where equipped

- If not within 25ºC (45ºF)

Refer to Circuit/System Testing.

- If within 25ºC (45ºF)

- Engine idling, verify the following scan tool parameters are between: -38 and +149ºC (-36 and +300ºF).

- IAT Sensor 1

- IAT Sensor 2

- IAT Sensor 3; where equipped

- If not between: -38 and +149ºC (-36 and +300ºF)

Refer to Circuit System Testing.

- If between: -38 and +149ºC (-36 and +300ºF)

- Operate the vehicle within the conditions for running the DTC. You may also operate the vehicle within the conditions that you observed from the freeze frame/failure records data.

- Verify the DTC does not set.

- If the DTC sets

Refer to Circuit/System Testing.

- If the DTC does not set

- All OK

Circuit/System Testing

NOTE: You must perform the Circuit/System Verification before proceeding with Circuit/System Testing.

- Check the integrity of the entire air induction system and verify that none of the following conditions exist:

- A loose or disconnected charge air cooler hose or pipe; where equipped

- A blocked or obstructed charge air cooler, including: after-market grill covers; where equipped

- Any snow or ice build-up at the charge air cooler in cold climates; where equipped

- Any mud or dirt build-up at the charge air cooler; where equipped

- A restricted or collapsed air intake duct

- An intake manifold leak

- A MAP sensor seal that is leaking, missing, or damaged

- A misaligned or damaged air intake duct

- Any water intrusion in the induction system

- An Intake Manifold Resonator with a leaking seal, or a cracked or broken housing

- If a condition exists

Repair or replace component as appropriate.

- If no condition exists

- Ignition OFF, and all vehicle systems OFF, it may take up to 2 min. for all vehicle systems to power down. Disconnect the harness connector at the B75C Multifunction Intake Air sensor.

- Test for less than 2 ohms between the low reference circuit terminal 7 and ground.

- If 2 ohms or greater

- Ignition OFF, disconnect the harness connector at the K20 Engine Control Module.

- Test for less than 2 ohms in the low reference circuit end to end.

- If 2 ohms or greater, repair the open or high resistance in the circuit.

- If less than 2 ohms replace the K20 Engine Control Module.

- Test for less than 2 ohms in the signal circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K20 Engine Control Module.

If greater than 5.2 V

NOTE: If the 5 V reference circuit is shorted to a voltage the engine control module or the sensor may be damaged.

- Ignition OFF, disconnect the harness connector at the K20 Engine Control Module.

- Ignition ON, test for less than 1 V between the 5 V reference circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V, replace the K20 Engine Control Module.

If between 4.8-5.2 V

- Ignition ON, test for 4.8-5.2 V between the signal circuit terminal 8 and ground.

- If less than 4.8 V

- Ignition OFF, disconnect the harness connector at the K20 Engine Control Module.

- Test for infinite resistance between the signal circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance

- Test for less than 2 ohms in the signal circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K20 Engine Control Module.

If greater than 5.2 V

NOTE: If the signal circuit is shorted to a voltage the engine control module or the sensor may be damaged.

- Ignition OFF, disconnect the harness connector at the K20 Engine Control Module.

- Ignition ON, test for less than 1 V between the signal circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V, replace the K20 Engine Control Module.

If between 4.8-5.2 V

- Ignition ON, verify the scan tool IAT Sensor 1 parameter is colder than -39ºC (-38ºF).

If warmer than -39ºC (-38ºF).

- Ignition OFF, disconnect the harness connector at the K20 Engine Control Module.

- Test for infinite resistance between the signal circuit terminal 8 and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance

- Test for less than 2 ohms in the signal circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K20 Engine Control Module.

If colder than -39ºC (-38ºF).

- Ignition OFF, install a 3 A fused jumper wire between the signal circuit terminal 8 and the low reference circuit terminal 7.

- Verify the scan tool IAT Sensor 3 parameter is warmer than 150ºC (302ºF).

If colder than 150ºC (302ºF).

- Ignition OFF, remove the jumper wire, disconnect the harness connector at the K20 Engine Control Module, ignition ON.

- Test for less than 1 V between the signal circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V

- Ignition OFF.

- Test for less than 2 ohms in the signal circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K20 Engine Control Module.

If warmer than 150ºC (302ºF).

- Ignition ON, test for 4.8-5.2 V between the signal terminal 1 and ground.

If less than 4.8 V

- Ignition OFF, disconnect the harness connector at the K20 Engine Control Module.

- Test for infinite resistance between the signal circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance

- Test for less than 2 ohms in the signal circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K20 Engine Control Module.

If greater than 5.2 V

NOTE: If the signal circuit is shorted to a voltage the engine control module or the sensor may be damaged.

- Ignition OFF, disconnect the harness connector at the K20 Engine Control Module.

- Ignition ON, test for less than 1 V between the signal circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V, replace the K20 Engine Control Module.

If between 4.8-5.2 V

- Determine if EL-38522-A Variable Signal Generator or equivalent is available.

- EL-38522-A, Variable Signal Generator; or equivalent is not available

- Replace the K20 Engine Control Module.

- Operate the vehicle within the Conditions for Running the DTC. You may also operate the vehicle within the conditions that you observed from the freeze frame/failure records data.

- Verify the DTC does not set.

- If the DTC sets

Test or replace the B75C Multifunction Intake Air sensor.

- If no DTCs set

- Circuits, ECM, and the sensors test OK, refer to step 18.

EL-38522-A, Variable Signal Generator; or equivalent is available

- Ignition OFF, connect the leads of the EL-38522-A Variable Signal Generator as follows:

- Red lead to the signal circuit terminal 1 at the harness connector

- Black leads to ground

- Battery voltage supply lead to B+

- Set the EL-38522-A Variable Signal Generator to the following specifications.

- Signal switch to 5 V

- Duty Cycle switch to 50 % (Normal)

- Frequency switch to 30 Hz

- Ignition ON, verify the scan tool IAT Sensor 2 parameter is between 28-32 Hz.

If not between 28-32 Hz

Replace the K20 Engine Control Module.

If between 28-32 Hz

- Ignition OFF and all vehicle systems OFF, disconnect the B111B Turbocharger Boost/Intake Air Temperature sensor. It may take up to 2 min for all vehicle systems to power down.

- Test for less than 2 ohms between the low reference circuit terminal 1 and ground.

If 2 ohms or greater

- Ignition OFF, disconnect the harness connector at the K20 Engine Control Module.

- Test for less than 2 ohms in the low reference circuit end to end.

- If 2 ohms or greater, repair the open or high resistance in the circuit.

- If less than 2 ohms replace the K20 Engine Control Module.

If less than 2 ohms

- Ignition ON, test for 4.8-5.2 V between the signal circuit terminal 2 and ground.

If less than 4.8 V

- Ignition OFF, disconnect the harness connector at the K20 Engine Control Module.

- Test for infinite resistance between the signal circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance

- Test for less than 2 ohms in the signal circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K20 Engine Control Module.

If greater than 5.2 V

NOTE: If the signal circuit is shorted to a voltage the engine control module or the sensor may be damaged.

- Ignition OFF, disconnect the harness connector at the K20 Engine Control Module.

- Ignition ON, test for less than 1 V between the signal circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V, replace the K20 Engine Control Module.

If between 4.8-5.2 V

- Test or replace the appropriate temperature sensor.

- All OK.

Component Testing

Multifunction Intake Air Sensor

- Ignition OFF, disconnect the harness connector at the B75C Multifunction Intake Air sensor.

NOTE: A thermometer can be used to test the sensor off the vehicle.

- Test the IAT sensor 1 by varying the sensor temperature while monitoring the sensor resistance. Compare the readings with the Temperature Versus Resistance - Intake Air Temperature Sensor (Bosch Sensor) , Temperature Versus Resistance - Intake Air Temperature Sensor (Delco Sensor) table for Bosch Sensors. The resistance values should be in range of the table values.

- If not within the specified range.

Replace the B75C Multifunction Intake Air sensor.

- If within the specified range.

All OK

Multifunction Intake Air Sensor

- Test the IAT Sensor 2 by varying the sensor temperature while monitoring the air temperature with a thermometer. Compare the readings with the scan tool IAT Sensor 2 parameter. The values should be within 5%.

If not within 5%

Replace the B75C Multifunction Intake Air sensor.

If within 5%

- All OK.

Turbocharger Boost/Intake Air Temperature sensor

- Ignition OFF, disconnect the harness connector at the B111B Turbocharger Boost/Intake Air Temperature sensor.

NOTE: A thermometer can be used to test the sensor off the vehicle.

- Test the IAT sensor 3 by varying the sensor temperature while monitoring the sensor resistance. Compare the readings with the Temperature Versus Resistance - Intake Air Temperature Sensor (Bosch Sensor) , Temperature Versus Resistance - Intake Air Temperature Sensor (Delco Sensor) table for the appropriate sensor. The resistance values should be in range of the table values.

If not within the specified range.

Replace the B111B Turbocharger Boost/Intake Air Temperature sensor.

If within the specified range.

- All OK

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Intake Air Pressure and Temperature Sensor Replacement for turbocharger boost/intake air temperature sensor replacement

- Mass Airflow Sensor Replacement for multifunction intake air sensor replacement

- Control Module References for Engine Control Module replacement, programming, and setup.

DTC P0097, P0098, OR P0099

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptors

DTC P0097

Intake Air Temperature (IAT) Sensor 2 Circuit Low Voltage

DTC P0098

Intake Air Temperature (IAT) Sensor 2 Circuit High Voltage

DTC P0099

Intake Air Temperature (IAT) Sensor 2 Circuit Intermittent

Diagnostic Fault Information

IAT Sensor 2

.jpg)

Typical Scan Tool Data

IAT Sensor 2

.jpg)

.jpg)

Circuit/System Description

The sensors listed below are integrated within the multifunction intake air sensor:

- Intake Air Temperature (IAT) sensor 1

- IAT sensor 2

- Humidity sensor

- Mass Air Flow (MAF) sensor

- Barometric (BARO) pressure sensor

The IAT sensor 2 and the humidity sensor share the same circuit. The IAT sensor 2 signal is displayed by the scan tool as Hertz (Hz) and ºC (ºF).

The sensors listed below share an ECM supplied 5 V reference circuit:

- IAT sensor 2

- Humidity sensor

- Barometric pressure (BARO) sensor

The sensors listed below share an ECM supplied low reference circuit:

- IAT sensor 1

- IAT sensor 2

- Humidity sensor

- Barometric pressure (BARO) sensor

IAT Sensor 2 - Temperature, Frequency Table

.jpg)

Conditions for Running the DTCs

P0097, P0098, and P0099

- The ignition is ON, or the engine is running.

- The Ignition voltage is at least 11 V.

- The DTCs run continuously within the enabling conditions.

Conditions for Setting the DTCs

NOTE: The scan tool display range is between -40 and +150ºC (-40 and +302ºF).

P0097

The ECM detects that the IAT sensor 2 signal is less than 10 Hz, colder than -60ºC (-76ºF), for greater than 5 s.

P0098

The ECM detects that the IAT sensor 2 signal is greater than 390 Hz, warmer than 150ºC (302ºF), for greater than 5 s.

P0099

The ECM detects that the IAT sensor 2 signal is intermittent or has abruptly changed for longer than 5 s.

Action Taken When the DTC Sets

- DTCs P0097, P0098, and P0099 are Type B DTCs.

- The ECM commands the cooling fans ON.

Conditions for Clearing the MIL/DTCs

DTCs P0097, P0098, and P0099 are Type B DTCs.

Diagnostic Aids

- With the ignition ON, when the engine is cold and not running, properly functioning IAT sensor 2 will gradually increase the scan tool IAT Sensor 2 parameters. This is due to the heat that is generated by the multifunction intake air sensor heating elements.

- The humidity sensor and the IAT sensor 2 signals are sent to the ECM on the same circuit. If the IAT Sensor 2 parameter displays the values: 10 Hz; -40ºC (-40ºF), and there are also Humidity Sensor DTCs, check for a circuit problem.

Reference Information

Schematic Reference

Engine Controls Schematics (Encore) , Engine Controls Schematics (Encore)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - Encore

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

Powertrain Component Views

Powertrain Component Views

DTC Type Reference

Powertrain Diagnostic Trouble Code (DTC) Type Definitions (LUV) , Powertrain Diagnostic Trouble Code (DTC) Type Definitions (2H0)

Scan Tool Reference

Control Module References Control Module References for scan tool information

Special Tools

EL-38522-A Variable Signal Generator

For equivalent regional tools, refer to Special Tools (Diagnostic Tools) .

Circuit/System Verification

- Ignition ON.

- Verify that DTC DTC P0641, P0651, P0697, or P06A3 is not set.

If any of the DTCs are set

Refer to DTC P0641, P0651, P0697, or P06A3 (ECM) for further diagnosis.

- If none of the DTCs are set

NOTE: To minimize the effects of residual engine heat and sensor internal heating elements, perform Steps 3 and 4 of this verification procedure only if the ignition has been OFF for 8 hours or more.

- Ignition ON.

- Verify the following scan tool parameters are within 25ºC (45ºF) of each other.

- Start-Up IAT Sensor 1

- IAT Sensor 2

- IAT Sensor 3; where equipped

If not within 25ºC (45ºF)

Refer to Circuit/System Testing.

If within 25ºC (45ºF)

- Engine idling, verify the following scan tool parameters are between: -38 and +149ºC (-36 and +300ºF).

- IAT Sensor 1

- IAT Sensor 2

- IAT Sensor 3; where equipped

If not between: -38 and +149ºC (-36 and +300ºF)

Refer to Circuit System Testing.

If between: -38 and +149ºC (-36 and +300ºF)

- Operate the vehicle within the conditions for running the DTC. You may also operate the vehicle within the conditions that you observed from the freeze frame/failure records data.

- Verify the DTC does not set.

If the DTC sets

Refer to Circuit/System Testing.

If the DTC does not set

- All OK

Circuit/System Testing

- Ignition OFF, and all vehicle systems OFF, it may take up to 2 min. for all vehicle systems to power down. Disconnect the harness connector at the B75C Multifunction Intake Air sensor.

- Test for less than 2 ohms between the low reference circuit terminal 7 and ground.

If 2 ohms or greater

- Ignition OFF, disconnect the harness connector at the K20 Engine Control Module.

- Test for less than 2 ohms in the low reference circuit end to end.

- If 2 ohms or greater, repair the open or high resistance in the circuit.

- If less than 2 ohms replace the K20 Engine Control Module.

If less than 2 ohms

- Ignition ON, test for 4.8-5.2 V between the 5 V reference circuit terminal 2 and ground.

If less than 4.8 V

- Ignition OFF, disconnect the harness connector at the K20 Engine Control Module.

- Test for infinite resistance between the signal circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance

- Test for less than 2 ohms in the signal circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K20 Engine Control Module.

If greater than 5.2 V

NOTE: If the 5 V reference circuit is shorted to a voltage the engine control module or the sensor may be damaged.

- Ignition OFF, disconnect the harness connector at the K20 Engine Control Module.

- Ignition ON, test for less than 1 V between the 5 V reference circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V, replace the K20 Engine Control Module.

If between 4.8-5.2 V

- Ignition ON, test for 4.8-5.2 V between the signal circuit terminal 1 and ground.

If less than 4.8 V

- Ignition OFF, disconnect the harness connector at the K20 Engine Control Module.

- Test for infinite resistance between the signal circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance

- Test for less than 2 ohms in the signal circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K20 Engine Control Module.

If greater than 5.2 V

NOTE: If the signal circuit is shorted to a voltage the engine control module or the sensor may be damaged.

- Ignition OFF, disconnect the harness connector at the K20 Engine Control Module.

- Ignition ON, test for less than 1 V between the signal circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V, replace the K20 Engine Control Module.

If between 4.8-5.2 V

- Determine if EL-38522-A Variable Signal Generator or equivalent is available.

EL-38522-A, Variable Signal Generator; or equivalent is not available

- Replace the K20 Engine Control Module.

- Operate the vehicle within the Conditions for Running the DTC. You may also operate the vehicle within the conditions that you observed from the freeze frame/failure records data.

- Verify the DTC does not set.

If the DTC sets

Refer to step 9.

If the DTC does not set

- All OK.

EL-38522-A, Variable Signal Generator; or equivalent is available

- Ignition OFF, connect the leads of the EL-38522-A Variable Signal Generator as follows:

- Red lead to the signal circuit terminal 1 at the harness connector

- Black leads to ground

- Battery voltage supply lead to B+

- Set the EL-38522-A Variable Signal Generator to the following specifications.

- Signal switch to 5 V

- Duty Cycle switch to 50 % (Normal)

- Frequency switch to 30 Hz

- Ignition ON, verify the scan tool IAT Sensor 2 parameter is between 28-32 Hz.

If not between 28-32 Hz

Replace the K20 Engine Control Module.

If between 28-32 Hz

- Test or replace the B75C Multifunction Intake Air sensor.

Component Testing

Multifunction Intake Air Sensor

- Test the IAT Sensor 2 by varying the sensor temperature while monitoring the air temperature with a thermometer. Compare the readings with the scan tool IAT Sensor 2 parameter. The values should be within 5%.

If not within 5%

Replace the B75C Multifunction Intake Air sensor.

If within 5%

- All OK.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Mass Airflow Sensor Replacement for multifunction intake air sensor replacement.

- Control Module References for Engine Control Module replacement, programming, and setup.

DTC P00C7

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptor

DTC P00C7

Intake Air Pressure Measurement System - Multiple Sensors Not Plausible

Circuit/System Description

The Intake Air Pressure Measurement System consists of 3 sensors: